Demand for vegetable processing equipment is strong and continues to increase. This development, combined with labor woes, has resulted in a shift to higher levels of automation. “Processors see an increased opportunity to invest in the right technologies to increase capacity and throughput with less staffing headaches,” says Nick Maglio of PROEX FOOD. For the company this means increased demand for equipment manufacturing, design engineering, mechanical and digital technology integration, installation, commissioning, training, and aftersales support.

Years ago in the sweet corn world, the company already started to apply its frozen/IQF and shelf-stable/canned domain expertise to the fresh-cut and tray-packed and vacuum-packed markets. “That decision has proven wise,” says Nick Maglio with PROEX FOOD. “We are considered the global market leaders in that segment.”

Forward-looking insights

For processors looking to invest in new lines, the company has good news. “We have agreements with several key suppliers that have kept material and component supply running and have several manufacturing locations around the world. It has enabled us to deliver several complete lines this year,” shared Maglio.

The company’s R&D engineers also anticipated some of the supply chain issues and took those into account as they started developing 2022 product launches. Furthermore, PROEX FOOD’s US headquarters was moved to a new location with a much larger warehouse last year and stocked to higher levels immediately while at the same time more inventory will soon be available in both Western Europe and the UK.

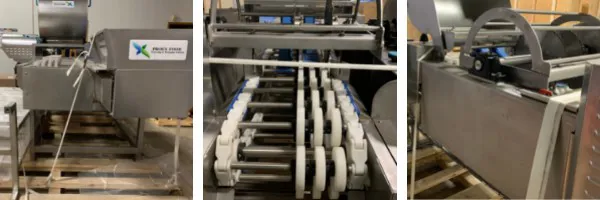

As a result of these insights and developments, a few extra units of sweet corn equipment are available to be shipped immediately. This includes huskers and saws that are in-stock and ready to be shipped on a first come, first serve basis. These individual machines are available to ship today (as of the time of this article being written), and can still be installed before the start of this 2022 season:

Cob / Vegetable Saws – 2021 models

- (1) at US HQ

- (1) at Europe warehouse

Huskers – 2021 models, configured for fresh applications

- (1) 4-Lane unit at US HQ

- (2) 8-Lane units at US HQ

Husker

Husker

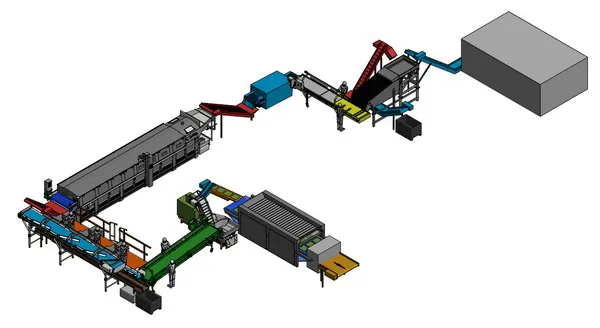

Additionally, a PROEX FOOD customer that took delivery of a complete line in 2020 is putting it up for sale. This entire line is in storage in the US and can be shipped immediately, preferably as a complete package. It is in completely new, pristine condition.

(1) 2020 model 4-Lane Husker and frame, configured for processed corn

(1) 2020 model 4-Lane Husker and frame, configured for processed corn- (1) Brush Washer

- (1) Belt Blancher and Cooler

- (3) Corn Kernel Cutters

- (1) Corn Juice Collection Tank

- (1) Boiler

- Central Controls

- Platforms and Conveyors

To further support processors, the company is preparing to launch a few new products in its iNTELLIPROTM product line shortly that provide new, impactful solutions. This would include a new iNTELLIPRO SAW as well as new iNTELLIPRO HUSKER for shipments this calendar year.

iNTELLIPRO Husker For more information:

For more information:

PROEX FOOD

sales@proexfood.com

Americas/Australia/New Zealand:

+1 414 626 5741

Europe/International: +48 22 185 75 87