With growers around the world crying out for pickers, more and more are looking at what technology is available to reduce their reliance on expensive and hard to find labour. The berry industry is continually growing in volumes and is particularly labour intensive and automation to harvest fruit for the fresh market can be hard to find in the sector.

King & Associates (K&A) have now brought a solution for berry growers in Australia and New Zealand. They are the distributors of the Kokan Air-Jet Berry Harvester which is manufactured by BSK in Serbia.

“We are very excited to bring this technology to New Zealand,” said Stuart Abbott from K&A. “The harvester is ideally suited for fresh blueberries, but can harvest raspberries, blackberries and blackcurrants successfully.

“Harvesting blueberries by hand is very labour intensive and also blueberries have a natural bloom (white dusting) and when they are handled by hand this is disturbed.”

“Harvesting blueberries by hand is very labour intensive and also blueberries have a natural bloom (white dusting) and when they are handled by hand this is disturbed.”

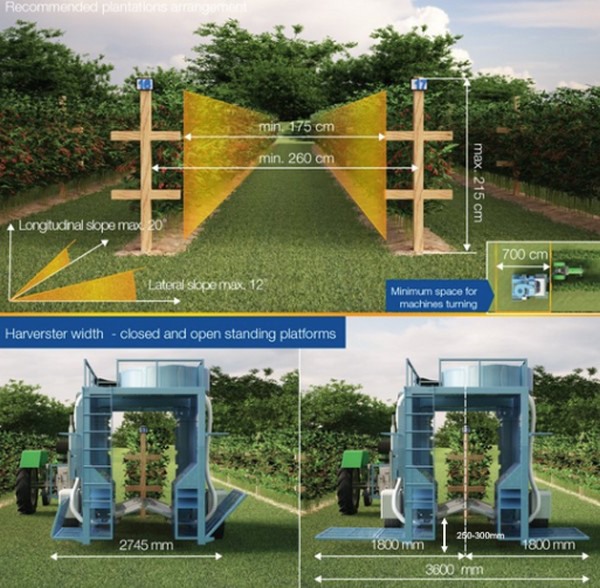

The machine harvests the berries using a combination of air velocity and pulsation which can be set to accommodate the variety and maturity of the fruit so that only the ripe berries will fall on to the inflated pillows on the catching plate.

The harvester operates from both sides of the bush and the pneumatic catching plates open and close to navigate around the plant base.

“Unsurprisingly demand is going through the roof. A machine with 4 staff can reduce picking costs by as much as 75% while delivering a high quality berry for the fresh market. The impact of approaching weather events can be minimized by the ability to harvest 10MT in a 12hr shift."

Lights can also be installed so the harvester can operate at night when it is cooler. Traditionally blueberry fields have been closely planted for hand harvesting, some may need a slight adjustment to accommodate the harvester as it needs a 7 metre turning headland but any bushes which need to be pulled out at the end of the rows can be used to fill the current gaps left for gathering full trays when hand  picking.

picking.

The big question is always what is the Return on Investment (ROI)?

“We have developed an electronic payback calculator where potential customers can put in their numbers and work out the ROI. The machine payback will differ depending on farm set ups and use, but on average the ROI is just 2 years.”

The harvesters are all sold with a spare parts kit and a full service network capability.

For more information:

Stuart Abbott

King & Associates NZ Ltd.

Tel: +64 21 117 5886

stuartjabbott@gmail.com