With CompoPac, the Franconian yarn and knitting specialist TVU has just launched a biological and very successful packaging net in 2020. A net with its own biological cycle from the natural raw material wood to the compostable devaluation: plastic-free and absolutely environmentally friendly. It helps to reduce and avoid unnecessary plastic packaging for food. "We are proud to be able to make our contribution to a future worth living with CompoPac," says Sales Manager Michael Bandel, acknowledging the work on CompoPac.

Michael Bandel

"One of our most important tasks at CompoPac at the moment is to build up stocks so that we can deliver even faster and more flexibly in the future." Michael Bandel also knows how to assess this project correctly, due to the current situation on the world market: "Although we already had the foresight to implement plans to increase and expand production capacities at the beginning of 2021, we have now also been somewhat slowed down by the current shortage of components and the worldwide supply problems," Michael Bandel explains. Nevertheless, TVU's commitment to implement last year's plans in the first half of 2022 and to double production capacity stands: "The conversion work on another large production hall is as good as complete, and the first machines are already running in the new hall. This will allow us to act even more flexibly in the future and we will be able to expand."

Conversion work for the new production hall

New machines

In addition, the high demand for CompoPac in recent months has ensured that stocks are very low. Nevertheless, Michael Bandel is confident despite the current supply bottlenecks: "We generally recommend planning ahead. The earlier we know the demand, the easier it is for us to reserve production capacities in 2022 and, if necessary, to organize partial deliveries." TVU's demands for a stable supply and, above all, long-term customer relationships are just as high as the requirements for product quality. Therefore, in addition to service quality and trust, the focus is above all on mutual appreciation of the business partners. "We always want to be a reliable partner. Therefore, we always strive to find the best solution for our customers," Bandel adds.

Production of nets from spools

Even though the next few months will not be easy in the fruit and vegetable sector and the overall situation in the packaging market remains tense, Michael Bandel sees the CompoPac brand continuing on its successful course. "As a role model in terms of environmental protection and with an ecological product that both the trade and European citizens can use without worry or bad conscience. No plasticizers, no questionable substances and biodegradable." The colored yarns, made from the raw material wood, are knitted into tubular nets in different sizes and are naturally food safe. In practice, the net is tear-resistant, resilient and also has a pleasant feel.

An absolutely unique feature of CompoPac is the enormous depth of the value chain: TVU procures the yarn in Europe, dyes it in-house and produces the nets into cuffs or rolls on its own machines. The company's own warehousing and logistics create a remarkable degree of flexibility, which benefits the customer alone. The in-house quality management with laboratory guarantees a consistent and high-quality product. CompoPac is the packaging net with a future: biological, environmentally friendly and climate-neutral.

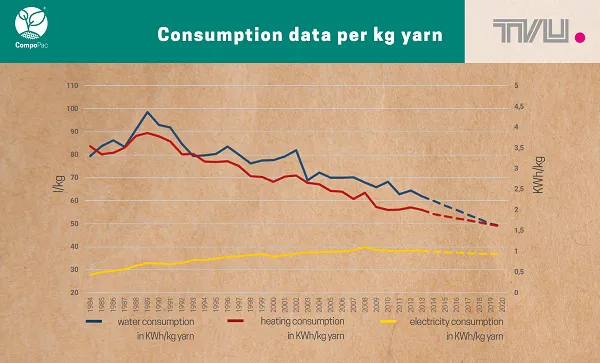

Consumption data

Sustainability and circular economy are a central goal - for the CompoPac brand, but also throughout the company. TVU generates 25 percent of its electricity with its own photovoltaic system. This saves around 500 tons of Co2 per year. In addition, the company produces about 20,000 megawatt hours a year with its own biomass heating plant and heat recovery system. Water consumption has been reduced by more than 40 percent over the past 20 years. "In addition to our service and the project work we have done, it is this sustainable overall concept that is highly appreciated by our customers," says Michael Bandel. He is certain that the fruit and vegetable sector will still face some challenges in the coming years, but is also confident that they can be overcome.

For more information:

CompoPac is a product from

TVU Garnvertrieb GmbH

Michael Bandel

D-91578 Leutershausen

Rammersdorfer Str. 8

Tel: +49 (0) 9823-955 160

Mail: info@compopac.de

Web: www.compopac.de