"We're currently the only packing company in Europe that packaging Brussels sprouts in paper," says Evelien Vanlerberghe. She co-owns the Belgian company Trypol Pack. "More and more supermarkets want less plastic film in their range. In France, using plastic in small packaging will be banned in 2022. That's not a specific obligation in Belgium and the Netherlands yet."

"But we'd like to be one step ahead of the market." They, therefore, wanted to develop a paper Brussels sprout packaging. It had to meet the 95/5 recycling standard. Evelien explains that this means you can use only five percent of other materials like glue, coating, or labels. "Not all countries use this benchmark. But we chose to make packaging that does comply with it. And, in a way that it can be exported everywhere."

That presented Trypol Pack with the challenge of finding suitable paper. "Most types of paper packaging are sealed. To enable that, it has a sealable coating. That coating often doesn't meet the 95/5 standard. Once you perforate the packaging, there's less paper. Even paper packaging with a little window no longer meets the norm," says Evelien.

Fine-tuning

They tested various kinds of papers and two different machines. In the end, Trypol Pack opted for a VDH concept paper and Jasa Packaging Solutions' Bag2Paper machine. "We could realize this project, partly thanks to the Flemish Agricultural Investment Fund's innovation support." Evelien explains that the machine uses a paper label to seal the top end of the paper bag. Super tape replaces the bottom sealing seam. The packaging is already being used but still needs a little fine-tuning.

"Being the first to start something requires the necessary expertise. One learns by doing." There are, therefore, still some challenges, she points out. "The label and the super tape have to be attached in the right place. Otherwise, the bag doesn't close nicely. And the paper tends to tear at the forming shoulder, mainly along the perforations. That, too, is a challenge." Vanhemens supplied the machine. They are working on this issue, as well as the machine's speed. The goal is 50 bags per minute.

Shelf life

The packages' front is perforated for product visibility. "You obviously can't compare that to flowpack or net bags. Those are in contrast to sustainable, innovative packaging," explains Vanlerberghe. Those perforations also seem to affect the Brussels sprouts' packaged shelf life. "They have a great shelf life in the paper, better than we expected. The perforated paper bag has an advantage. No condensation - which is detrimental to the Brussels sprouts' shelf life - forms in the bag."

Convinced

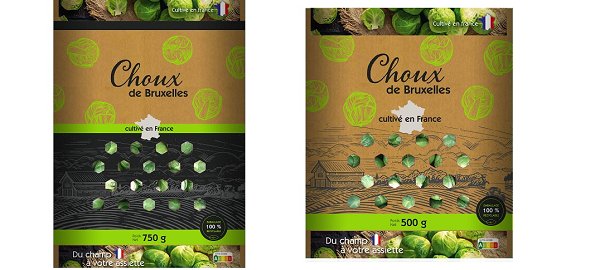

Trypol Pack supplies Brussels sprouts throughout Europe. The company has begun designing 750g packs in all languages. "We're now also working on a 500g package, as requested by several customers." Trypol Pack does not only do business in Belgium, the Netherlands, and Germany. It sells a good portion of its Brussels sprouts to the French market. From this year, that country has special packaging requirements. "There, you can no longer use plastic film in packs smaller than 1.5kg."

That is why Trypol Pack is busy developing a 500g pack specifically for the French market. The Brussels sprout packer has given samples to its Belgian and German retail customers too. And Evelien is pleased with the positive reactions she is getting. The only negative comment is about the packaging's lower product visibility. Evelien is happy to live with that. That lack of a visibility window ensures you can fully recycle the packaging.

The cost is a point of concern. Paper already used to cost more than, say, a flowpack. And in the past year, paper costs rose another 45%, Evelien points out. "Hopefully, the supermarkets are willing to pay more for this compared to the regular packaging that's on the market now. We're convinced this is the way to go. Paper suppliers will continue to innovate. So, we hope paper packaging prices will drop," she concludes.

Evelien Vanlerberghe

Trypol Pack bvba

7de Geniestraat 40

8650 Houthulst

België

+32(0) 495 3327 99

info@trypol.eu