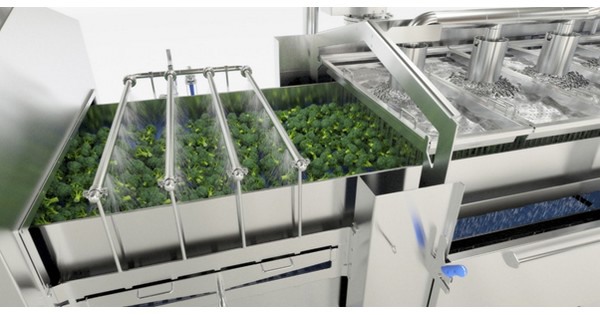

Swedish IQF machinery manufacturer OctoFrost has released a new 3D animation to allow potential customers to get a comprehensive understanding of the OctoFrost IQF Vegetable Processing Line.

According to Sana Rehman, marketing coordinator of OctoFrost, the animation shows off the convenience of using the OctoFrost line: “Our IQF Vegetable Processing Line is an all-in-one solution for vegetable processors around the world. According to our client Unilever, ‘The design and ease of sanitation make fast product changes possible’ and we feel this animation shows the properties that make our line so convenient. The sophisticated and technical aspects of the IQF Vegetable Processing Line are presented, showcasing properties of each piece of machinery; the flotation Washer with aerial blower, OctoFrost IF Blancher, Flash Chiller, and IQF Vegetable Freezer. Working together with industry experts and graphic designers, OctoFrost achieved a complete visual representation that shows how food products are processed at each stage of the washing, blanching, chilling, and freezing processes.”

Rehman states that their Vegetable Processing Line makes use of technology that tackles a lot of the industry’s challenges. “OctoFrost’s use of the latest Impingement Flash technology, a cross-flow Rain Shower System and water Recirculation System, ensures 90% less water consumption compared to other systems, 30 to 40% reduction in steam consumption, quick heat transfer and fast chilling as well as precise temperature control. In addition, the unique aerodynamics of the IQF Freezer and three optional bedplate movements solve common industry challenges related to product separation, dehydration and energy consumption.”

Another feature of the line is the ability to autonomously clean itself, Rehman explains: “OctoFrost IQF Vegetable Processing Line is also equipped with a Cleaning-in-Place (CIP) system, which makes it a self-cleaning, fully automated processing line. In addition, it has exchangeable bedplates with a puzzle connection that allow cleaning and sanitation outside the freezer, while avoiding cross-contamination of different batches of products. The line is also equipped with a coil Snow Removal System for efficient foaming cleaning and rinsing.”

“These characteristics of the OctoFrost Vegetable Processing Line make it the most energy-efficient and sustainable product in the market, which guarantees premium product quality, high yields, and the greatest hygiene and food safety standards in the industry.” Rehman concludes.

For more information:

OctoFrost Group

Email: sales@octofrost.com

www.octofrost.com