Corné Ooms is the self-proclaimed 'Asparagus farmer from Ossendrecht', [a Dutch village]. Five years ago, he began processing soft fruit. Corné gained a major supermarket customer, and the business expanded considerably. So much so that its premises became too small.

A few years on, and Bieze Food Group has joined Corné's company, Brabantsche Wal, as an investor. This fruit and vegetable relocated to the former Holland Crop premises in Ossendrecht. And in addition to red fruit and asparagus, they also process apples and pomegranates. "Our focus is, however, on soft fruit and convenience," says Corné.

Edward van den Eijnden and Corné Ooms in front of the new building.

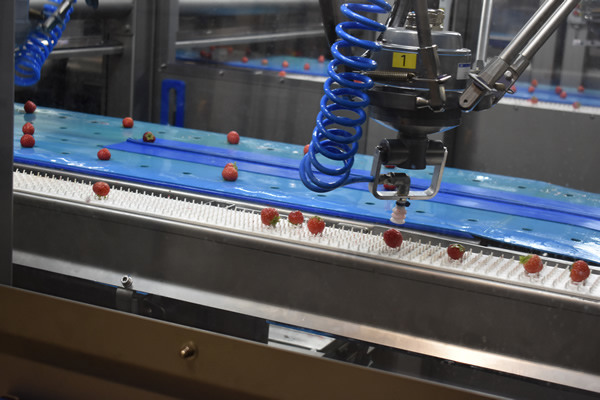

"I saw red fruit processing developments while in the United States. And I saw opportunities for the European market. This turned out to be a gap in the market. When we got that supermarket client, things started moving fast. We specialize in soft fruit so aren't in direct competition with many processors. We don't venture into products like pineapple and mango either. Buyers quickly found their way to us. We started with a couple of employees, slicing up the fruit by hand. Now, we have six machines. We de-core many tons of strawberries every week."

Wernsing Food Family

There came a point, three years ago, when something had to be done. The growing demand needed to be met. "We needed a substantial capacity expansion. Then you can either go to the bank or look for an investor. I very quickly decided on the second option. I got talking to Frank Bieze of the Bieze Food Group. He was interested. And, thus, we became the 13th CC under this group in the Benelux," explains Corné.

He is delighted with the parent company. "The Bieze Food Group is part of the German Wernsing Food Family. That group of 90 European companies has a €1.4 billion turnover. It's a true family business. It considers continuity, sustainability, and long-term prospects paramount. They don't get nervous easily and let the business people go about their business. Within limits, of course."

This investment enabled the relocation. Corné knew the premises of Holland Crop premises was to become vacant. This is in his home village of Ossendrecht. So, he made a telephone call. Thus Brabantsche Wal quietly became the owner of the new 4,000 m2 building.

"We bought the property in March 2020. But another company remained active there until mid-September. On October 1st, we started a large-scale conversion into a high care processing site. We moved on April 4th of this year, in the middle of the Easter break. Our customers didn't notice a thing. They all got everything they ordered," says Corné proudly.

Benefit of synergy

He considers his new location ideal. "It's not tucked away in an industrial area. It's in a beautiful spot behind the woods. What more could you want? I also know the locals, which is great for attracting new employees. We may not be centrally located in the Netherlands. But from a European perspective, we certainly are. And clients increasingly recognize that."

"We have very definitely experienced the benefits of synergy with the group's other members too. For example, there are IT and internal logistics specialists within the Bieze Food Group. They came to help us set up. Not expensive consultants; people who know exactly what you need at a time like that. The holding company also takes care of the HR policy. The group aids us tremendously well," Ooms continues.

Fifty people used to work at Brabantsche Wal's previous 800 m2 plant. Now, they employ 80. "I don't want to move towards more people. We want to do as much with automation as we can. I've always loved new ideas and always see opportunities in them. A relatively small company has an advantage. You can just implement great ideas. There's no management layer with all kinds of reservations. Sometimes you simply have to dare to come up with something that doesn't exist. Komatech carries out my plans. They've built some fantastic machine lines already."

Corné has also invested heavily in strengthening his company. "Two years ago, I was managing everything myself. Now, we have a staff of eight or nine. That's quite a lot of people. But it allows me to do the things at which I'm good. And it provides us a solid organization. I want to remain extremely flexible. That's despite our increased capacity; we grew 50 or 60% in the past two years. We have three trucks and three refrigerated vans. We want to be able to deliver to our customers at all times. 'Can't' isn't an option."

Combining products

Fanny van Gestel was the first skilled worker the company employed. And since November 2020, Edward van den Eijnden has been purchasing all their fruit. Edward recently worked for Angus Soft Fruit. He is, therefore, very familiar with the whole fruit world. A few years ago, he temporarily left the sector to take care of his wife. Things improved, and the Brabantsche Wal opportunity came at just the right time.

"I feel truly at home here. We mostly work on innovations, and that greatly appeals to me. For instance, we make numerous soft fruit product combinations. But we combine these with dairy products too. We supply a whole range of yogurt, granola, and fruit," Edward says.

Edward van den Eijnden

"We work with pure products and use no sweetened fruit juices. We're the only ones that meet the NutriScore A. This branch is growing rapidly. We're hard at work on further product development, such as vegan yogurt and fruit smoothies. Our advantage is that we only have to buy what our customers need."

"So, there's much less sales pressure than at a traditional trading company. But you have to be able to deliver. This summer, too, we achieved a 100% load factor. That was no mean feat, considering the last four weeks' shortages. Strawberries were selling for €10/kg in the middle of the summer," Edward explains.

Brabantsche Wal's clients are local and overseas retailers. But other processors know where to find the company too. "Our group's philosophy is to serve retail market leaders personally. We use service providers for the other supermarkets. That fits in perfectly with our business operations," says Corné. He still grows and processes asparagus for Brabantsche Wal.

"That's my baby, after all; you can't rid me of that. We're certainly not one of the country's largest growers. But we have our buyers and serve a nice niche market. Customers experience the benefits of having a Brabantse Wal label on their asparagus. Also, it fits in very well with our other activities. People often mention strawberries and asparagus in the same breath."

Three large apple peeling lines

Processing apples is an entirely new thing at the company. "We had extra space in the new building. I'd heard of an apple processing company that was for sale. I made an offer, and we quickly struck a deal. And, so, that apple processing company came to us. We took over their customers, and Cees Pattenier, whose company it was, runs daily operations from here," Corné explains

"Until last September, I had never done anything with apples. Now we're in the thick of it. I stumbled across an online auction of apple processing machines in Germany. Cees and the guys from Komatech went to have a look. They were immediately convinced. And that's how we came to own three large apple peeling lines. And how our capacity suddenly increased fivefold."

"We had a very nice peeling season, despite the apple market shortages. Edward could make good use of the old network he'd built at Frutera Crop. We can supply all cuts, from cubes to slices. Many people hear we're in the apple processing business and start inquiring. Places like bakeries, for both fresh and frozen products, come knocking," continues Corné.

The apple peeling lines

Pomegranate pips

The factory still had a small unused area. And, Corné being Corné, found a use for it. Brabantsche Wal's newest branch consists of pomegranate pitting. "Pomegranate pips are a booming market. But presently, they mostly arrive by air freight from countries like India and Egypt. There, they pit the fruits by hand. The delivery reliability isn't great, and there are questions about sustainability."

"That's why we invested in a de-stoning machine." The company now does 300 to 400kg/hour. These pips also have a ten-day shelf life. "There's plenty of supply in the Mediterranean season. That's now started. But during the last overseas season, it was quite challenging to get enough volume. We've, however, learned our lesson. We'll be able to guarantee good volumes next season," Corné adds.

The pomegranate pitting machine

"After avocadoes and blueberries, pomegranate pips are the latest hype. And many customers know we offer these. We supply them to retailers in punnets. And 10 kg loose to fellow fruit processors. These clients are local and overseas. The great thing is that, with these pips, we create a new producer category."

"The fruits' external quality and skin damage aren't so relevant for us. The pips must just have good color. This product is normally used in juice or IQF. We increase the product's added value."

Product development is not standing still either. Last year Brabantsche Wal supplied a Dutch supermarket with machine-pitted cherries. "We continue to develop, but within red fruit and convenience," Corné concludes.

For more information:

For more information:

Corné Ooms / Edward van den Eijnden

Brabantsche Wal

54 Laag Street

4641 SP, Ossendrecht, NL

Tel: +31 (0) 332 050 979

Email: c.ooms@brabantschewal.nl

Email: e.eijnden@brabantschewal.nl

Website: www.brabantschewal.nl