Commercial products are constantly adapting to consumer purchasing trends, taking into account their lifestyle, culinary traditions, where they live, and so on. But one thing that is of top priority among westernized countries is a lifestyle based on a healthy balanced diet.

As a result, today's consumers are moving towards conscious choices, paying more attention to the nutrients needed by the body, while trying to eliminate anything that may cause health problems. This has caused a major reversal in the last few years and has prompted food companies, particularly fruit processors, to provide alternatives to the increasingly less sought-after tasty snacks.

Virginia Cascella, export manageress at PND, a leading company in the sector of industrial machinery for the processing of fruit and vegetables, which for decades has been making state-of-the-art machines for companies producing fresh fruit, spoke on the subject.

Vincenzo Di Prisco (general manager PND) and Virginia Cascella (export manageress PND)

Vincenzo Di Prisco (general manager PND) and Virginia Cascella (export manageress PND)

Dehydrated fruit has become a choice for people of all kinds, especially athletes, children and pregnant women. Many nutritionists recommend apple chips as the most sought-after dehydrated fruit, partly because of their shape, which is reminiscent of crisps in a bag, and partly because of their naturally sweet taste, which satisfies the desire for something sweet," said Cascella.

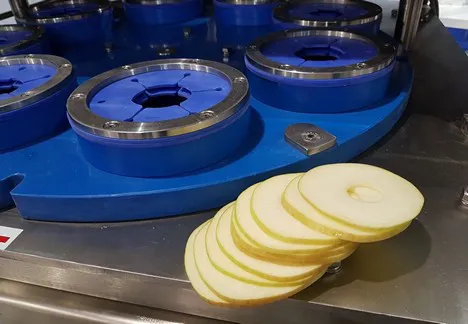

Coring and slicing machine RR8 model

"To obtain apple slices, PND proposes two specific machines, the DRR tool and die cutter (pictured here) and the RR8 slicer. The DRR washer is a stand-alone machine and it does not need to be combined with other machines in order to perform a complete and optimal cut. It indeed detours and cuts into rings, thanks to a SMART system of synchronized mechanisms. The fruit is loaded manually, while everything else is done automatically. The RR8 machine, on the other hand, is a washer capable of processing more than 60 fruits per minute. In order to be able to cut, however, the apple (or peach) must be placed in its housing after being cored (and peeled, if you prefer). This is why it is advisable to combine the RR8 washer with a peeler and de-seeder (PL8 | PL6 | PL4 | PL2) to complete the task,” explained the manageress.

DRR tool and die cutter (pictured here) and the RR8 slicer. The DRR washer is a stand-alone machine and it does not need to be combined with other machines in order to perform a complete and optimal cut. It indeed detours and cuts into rings, thanks to a SMART system of synchronized mechanisms. The fruit is loaded manually, while everything else is done automatically. The RR8 machine, on the other hand, is a washer capable of processing more than 60 fruits per minute. In order to be able to cut, however, the apple (or peach) must be placed in its housing after being cored (and peeled, if you prefer). This is why it is advisable to combine the RR8 washer with a peeler and de-seeder (PL8 | PL6 | PL4 | PL2) to complete the task,” explained the manageress.

Both machines have a food-grade stainless steel structure and, depending on requirements, can be fitted with swivel wheels with brakes or adjustable rubber feet. At the end of the slicing process, the processing line can be completed with a treatment tank to prevent the product from turning brown quickly, but this last detail is up to the customer."

The company will be present at Macfrut 2021 with a stand of 32 square metres, open on two sides.

For more information:

Virginia Cascella

PND - Fruit Processing Machinery

Via Brancaccio, 11

84018 Scafati (SA) – Italy

+39 0818509368

info@pndsrl.it

www.pndsrl.it