The Covid-19 cargo congestion brought on by extreme demand in combination with operational disruptions is very real and felt across supply chains globally. In the U.S. in particular, all parts of the supply chain are facing unprecedented pressures – there is a lack of rail and truck capacity, warehouses are full, and ports are bursting at the seams. It is in part in this context that the President is issuing an Executive Order that addresses shipping along with other industries.

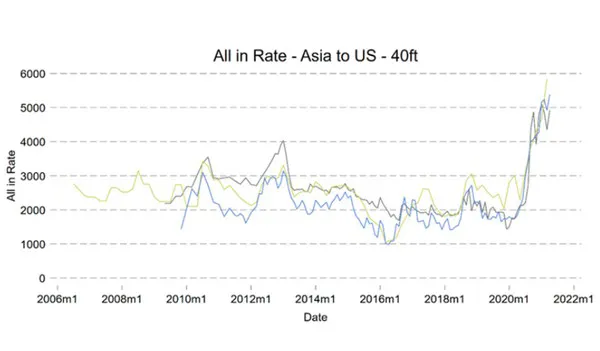

The driver of these problems is demand for imports by U.S. consumers and U.S. businesses. Of the past 12 months, 11 months have had a year-on-year growth in spending on consumer goods of over 10%. To put this into perspective, in the 18 years before the pandemic, the average growth rate was 4.7%.The impact of this sustained increase in spending on consumer goods is manifested in the volume of U.S. container imports stressing the supply chain. In its most recent assessment of market conditions, Drewry Shipping Consultants concludes: “The surge in Asian exports being shipped to North America continues unabated. In the first three months of 2021, eastbound volumes grew by 34% - the highest quarterly gain by far since Drewry’s current records began in 1995.”

Ocean carriers are employing all available capacity and pulling out all stops to manage the operational disruptions brought on by Covid-19. But when marine terminals cannot clear the cargo already on the docks, ships cannot berth to discharge and load cargo. And marine terminals cannot clear cargo if the importers of that cargo have no warehouse or distribution space to put those containers. And containers are stuck in many places in the U.S. waiting for adequate rail and truck capacity to move them.

“This is not the fault of any given supply chain actor. Supply chains simply cannot efficiently handle this extreme demand surge, thus resulting in the delays, disruptions and capacity shortages felt across the chain. All supply chain players are working to clear the system, but the fact is that as long as the massive import demand from U.S. businesses and consumers continues, the challenges will remain,” says John Butler, President & CEO of World Shipping Council.

Liner shipping remains highly competitive, and lack of competition is not the cause of the cargo congestion

The industry remains competitive by any measure, and the current situation is not caused by any lack of competition. There are over 50 ocean carriers operating more than 1,000 ships that provide some 180 liner services to U.S. importers and exporters.

Click here to read the full Press Release.

For more information:

Anna Larsson

World Shipping Council

Tel: +47 484 06 919

Email: alarsson@worldshipping.org

Anne Marie Kappel

Email: akappel@worldshipping.org