Two pilot studies from the Queensland Government's Department of Agriculture and Fisheries are looking at improving the competitiveness of Australian vegetable exports, in partnership with two major producers.

The research was presented to delegates at the Queensland Horticulture Export Congress, held in conjunction with Hort Connections. The project was split into two focuses; firstly, improving the consistency of sea freighted broccoli into Asia and secondly, how to successfully sea freight mixed vegetable loads to short-distance markets, such as New Zealand.

The first pilot is being run in partnership with Kees Versteeg from Qualipac, who says that the biggest challenge with exporting is weighing up the cost of air freight with the transportation time of sea freight.

"Around five years ago, we thought if we wanted to compete on price we had to choose sea freight because that would be the cheapest option to get it over there," he said. "The challenges are that your product is in transit 7-14 days and shipping by sea is a higher risk than shipping it by air freight. You have to take the good with the bad; you either send by air and don't get the sales because they are not willing to pay for it, or go by sea and take the risk but get it to the price point where the customer is willing to pay for it. The challenges are that you can put your product in transit, you can put the best products in the container, you can get the temperature, humidity, air circulation right - but it can still arrive (damaged). Believe it or not, inside the container, there are temperature variations. You would think that you put it in the container, close the door and set it at zero degrees, you think that it will be right. But it ended up being hit and miss. Some of the containers have issues with the technology. Not every container that leaves is perfect."

Photo: Kees Versteeg from Qualipac and Shane Quinn from Mulgowie Farming Company (seated), and Jodie Campbell.

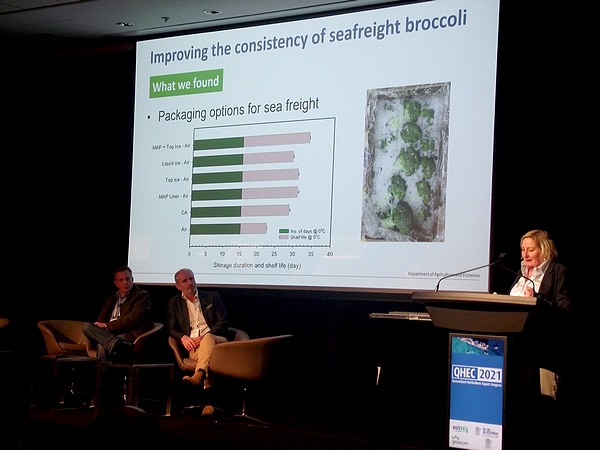

Principal Horticulturist Jodie Campbell explained that the pilot is looking at getting consistency with the broccoli exports in place. It involved getting "back to the basics" and looking at the data from the exporting businesses to review what was happening with the temperature monitoring, quality assessments and pre-shipment handling processes. She says the study also looked at storage duration time and temperature and a range of different packaging and icing options.

One of the main findings was that has found that temperature management at harvest is critical, particularly protecting the crop once it is harvested from exposure to the sun.

"From the analysis of data from the sea freight containers, we saw that we were looking at two-degree variances from those containers, and fluctuations throughout the container," Ms Campbell said. "What we are seeing is that the ice is melting because it is not sitting at zero, and in some cases melting then re-freezing, which is causing that damage to the broccoli. But when we did the simulations, because we were able to keep the consistent temperature, we weren't seeing the damages to the stems and heads. Almost always, at zero-degree temperatures, we are seeing the best shelf-life of broccoli. So, any increase in temperature - by even one degree - is going to shorten that shelf life. The challenge is predicting shelf-life; if we had that predictability, if we can let the customer know if the temperature has gone higher than two degrees. The end of shelf life was determined by the softening of the broccoli heads."

She added that there are further opportunities to explore the different packaging combinations between ice and modified atmosphere plastic (MAP) liners. The only issue with the latter is meeting phytosanitary and fumigation requirements.

Photo: Ian Layden

Ian Layden from the Department of Agriculture and Fisheries told the congress that the closure of borders due to COVID-19 in 2020 created some extra challenges for exporters.

"Queensland veg exporters were still geared up to make good on their promises to export broccoli, lettuce, green beans and sweet corn to markets in Asia and New Zealand, for example, and at that time International Freight Assistance Mechanism (IFAM) was not around," he said. "Growers knew to maintain competitiveness and transition to sea freight would be a challenge, but at the time, it was the only option. The data (from these pilots) will be important to make decisions on supply chain issues."

The second pilot looks at combining different vegetables within the one container shipment, which is important for growers to continually supply the market quickly and economically, rather than waiting for a full container of the one commodity less frequently. Ms Campbell explains that vegetables like green beans and sweet corn, for example, have different optimum temperatures and working with Mulgowie Farming Company, she explored how to trade off and set the container temperature to get the most shelf-life out of both

"We decided that we would look at the time and temperature durations, or what we call the sea simulations," she said. "We looked at four different temperatures for sweet corn and kept it at that for six days to simulate the time they were in the container to New Zealand. Then we took them out of those temperatures and had them in a retail or home shelf environment until they reached their end of shelf life. We then did the same with green beans but at slightly higher temperatures for those six days. We also had different packaging options; pre-packs, loose and different films and we found you do get a bit of variation between packaging. What we can see is we still have a residual shelf life of 10 days in the market. It is trading off a few days of shelf life, but with the mixed shipments, we can send them three times a week and still get at least seven days. So, yes, we can do the mixed loads, we just need to have an understanding of what we are mixing together."