Linde Material Handling (Linde MH) has launched its new forklift models. That was during a virtual press conference. The new Linde X20- X35 forklifts have a load capacity of 2.0 to 3.5 tons. That makes them the first electric forklifts to match Linde's hydrostatic forklifts' performance. These are powered by an internal combustion (IC) engine.

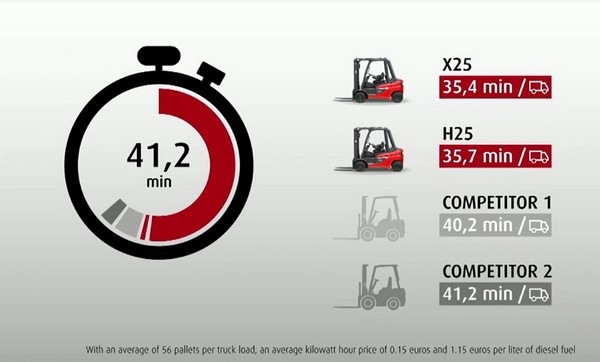

Electric forklifts' performance used to be was inferior to those using IC engines. But that tide's now turned. Linde HM developed a comparative TUV-certified performance test. This showed that the X20-X35 series was as powerful as the H20-H35 series. That was in terms of material handling. It even scores higher than competitors' models.

While developing these forklifts, Linde visited 300 clients. They got feedback from buyers across Europe. Using this, they developed this new electric forklift line - to meet customers' wishes. "We take our clients' opinions very seriously. They use these machines every day. So, they know better than anyone what's needed to make the work process easier. We developed this product based on their needs. It has the sturdy features of an internal combustion engine forklift. Plus the environmental benefits of battery operation," says Johannes Hössbacher of Linde MH.

E20-E35 Series

A demand for a highly maneuverable forklift also arose. It had to be suitable for indoor use on slippery industrial floors and in narrow aisles. The E20-E35 series was developed to meet this need. These forklifts can turn in place. But they're based on the same platform as the Linde H20-H35 and the X20-X35. That ensures shorter delivery times and an almost identical operator control system.

Top features

Several of the new models' features were highlighted at the press conference. Operator visibility has been optimized by things like narrower mast shafts and a glass roof. The machines are also shock-resistant. That ensures a comfortable working environment for the driver. "The X20-X35 series can navigate steep gradients and reach high handling speeds for long periods. They're not sensitive to dust and dirt either. These models can easily handle uneven terrain, just like the H20-H35 series. This makes them very suitable for outdoor use too," says Johannes.

With these new models, Linde wants to respond to companies' need to make their logistics cleaner and more sustainable. "Companies are often skeptical of electric trucks. They claim they're inferior to IC vehicles. However, with these models, businesses are taking the plunge - they're switching to electric forklifts," says Phillip Stephan, also of Linde MH.

New semi-automatic order picker

In addition to the new forklifts, Linde also presented a new semi-automatic order picker. "This machine uses ultra-wideband technology. That determines the employee's relative position. The picker then moves through the warehouse on its own. This new order picker means a 20% higher picking performance," concludes Phillip.

The new N20 SA and N20 C SA order pickers improve warehouses' efficiency. For example, operators no longer need to get on and off the machine. That saves time and operator energy. These new order pickers should pay for themselves within a short time. That's thanks to the time saved on routes, greater ease of use, and higher performance.

For more information: Website: www.linde-mh.com

Website: www.linde-mh.com