Belgian engineering firm FAM's like to keep their doors open. They help companies who want to test applications or machines. However, in March last year, the COVID-19 pandemic hit. So traveling and visiting trade fairs and companies became virtually impossible. Still, companies, including those in the food sector, need machines. But it's not very wise to buy one without having seen or tested it. That's why FAM came up with a virtual slicing test. This demo allows customers to test machines and its uses remotely.

Behind the camera, Bent Devreker and Tim Van Win prepare for a test. Two machines are standing at the ready. There's the Centris, a grater, and the Dorphy, a cubing machine. "We're currently in FAM's lab. Fam's been doing cutting tests and product development since it was founded. We prefer to do that onsite with the client present," says Bent.

"But, in the last 18 months, that's been much harder. So, this is how we want to show customers what our machines can do. And how they're operated and what's possible." So, FAM set up professional audio-visual equipment in its labs. They go through the entire processing process with the client. And they try to find the best method.

FAM Centris

Bent begins the demonstration by explaining the Centris 315. This is a small grating machine. It's used mainly by small and medium-sized fruit and vegetable companies. It's highly suitable for processing products like carrots, beetroot, potatoes, and onions. During the demo, the user-friendly machine grates carrots in no time into a delicious, fresh end product.

Bent shows how safe and easy the machine is to use. "The slicer is easy to install and dismantle. Our Centris technology has a precise slicing technique. That preserves the product's juiciness and freshness. And significantly contributes to a longer shelf life."

Interactive

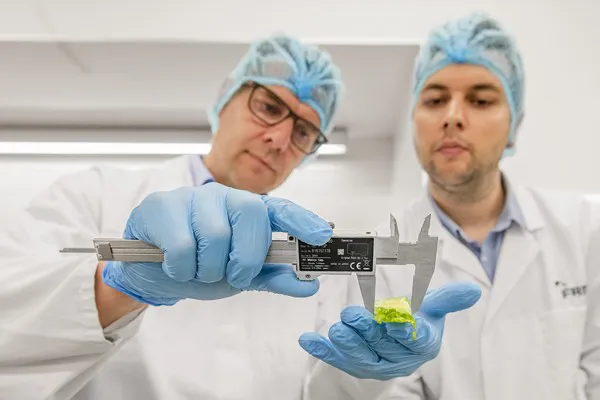

Viewers can ask questions at any time during the machines' demonstrations. And they can see it, and the product, up close. That's thanks to the use of several cameras. "It's very interactive," says Tim Van Win. "We can show all kinds of different cuts and parts of the machine. We also explain, in detail, how to operate and maintain the machines." FAM has all the machines available in the lab. They not only demonstrate these. They also provide implementation support and product development - all digitally. "Along with the client, we develop the perfect cut."

FAM Dorphy

The second machine on display is the Dorphy. This has several sets of knives. You can use these to slice, shred, cube, and cut fries of all different sizes. Slicers are central to any processing machine. These are shown during a close-up of the open machine. Stumabo, FAM's sister company, produces this component for all the machines. After demonstrating the machines, there's plenty of opportunity for questions or additional explanations. And FAM allows sufficient time for this.

“By offering processing tests, we can support companies in their quest for the best cut. We don't see ourselves as salespeople but as advisors. We, along with the clients, look for the right solution," says Tim.

“By offering processing tests, we can support companies in their quest for the best cut. We don't see ourselves as salespeople but as advisors. We, along with the clients, look for the right solution," says Tim.

"Even if the requirements are very high. We've built up knowledge over all these years. We use that to provide every solution. And if we don't have it, we develop it."

“Even now, during the pandemic, businesses can approach us. And we can digitally share our passion with food industry companies. As well as our know-how, quality, experience, and new ideas," Tim and Bent conclude.

For more information: FAM

FAM

2 Neerveld

2550, Kontich, Belgium

Tel: +32 (0) 345 09 245

Email: info@fam.be

Website: www.fam.be