Kuku International Packaging, a company specialized in flexible packaging and located in Palata Pepoli, in the province of Bologna, Italy, launched a new plastic-free packaging solution entirely made of virgin cotton fiber, with no plastic in it, that can be used with packaging machines.

"It is part of our plastic-free line for filling bags both automatically and manually. It has been tested on garlic and onion so far, on a national and European scale. The new pack is already being used by some of our customers. With only a few adaptations on the machines, companies can immediately switch to this packaging, which consists only of fibers of vegetable origin," explained Serena Ruppi, CEO of Kuku.

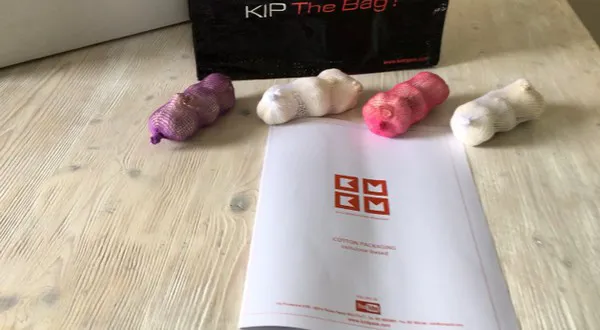

Photo provided by Kuku International Packaging

Photo provided by Kuku International Packaging

A European Union-wide shift to reduce the use of plastics is well underway, with the goal of total or near-elimination by 2030. "We have been working with plastic-free fibers for some time now, with a proven track record. In recent months we have been conducting tests, with the new feature of adapting these materials to existing machineries," continued Ruppi.

Virgin cotton fiber has greater flexibility than other commercial plastic alternatives. "It's not as elastic as plastic, but it's closely similar to it. We could say this is the first plastic-free product that resembles the same results of plastic-knitted tubular nets, a key factor in the packaging of some products. Customers who are using our material are very satisfied, as it allows for an ecological three-piece package for garlic and onion heads, required in supermarkets," explained Kuku's CEO.

Photo provided by Kuku International Packaging

Photo provided by Kuku International Packaging

Ruppi firmly believes this is the path to pursue. "There will be an exponential increase in demand for packaging made from increasingly natural materials. Undoubtedly, the market must be able to adapt, also because of the European directives concerning the reduction of carbon dioxide by 2030. Plastics produce large quantities of carbon dioxide.

"We are adapting to an inverse cycle. We use fiber derived from plants, which absorb CO2, releasing oxygen. An upstream ecological process. In all fairness, cotton uses a lot of water, so it has a bigger impact on the environment, but we are carrying out a new project with a new natural fiber that uses very little water," concluded Ruppi.

Kuku International Packaging promises that there will be more to come.

For more information:

Serena Ruppi

Kuku International Packaging

Via Provanone 4100

40014 Palata Pepoli (Bologna) - Italy

+39 (0)51 6830969

info@kintpack.com

www.kintpack.com/index.php/it