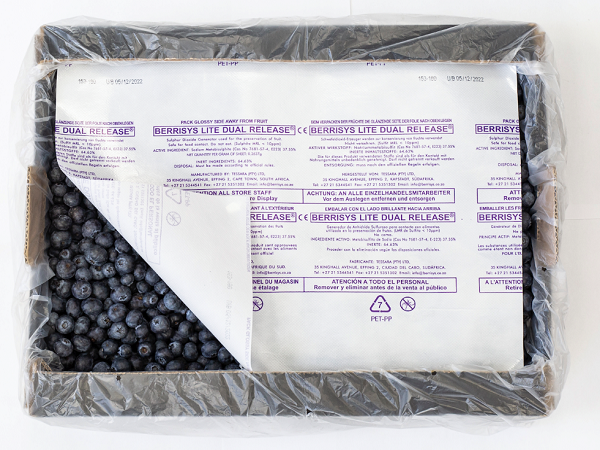

South African grape growers are well acquainted with the Tessara Uvasys generators that extend the shelf life of their grapes through surface sterilisation. Last year, blueberry exporters came to rely on Tessara's new Berrisys range; in one instance where an exporter's containers were stuck in ports for three or four weeks longer than they'd anticipated, thanks to the controlled release of sulphur dioxide by the Berrisys sheets, the fruit was still marketable.

But that, as Alwyn van Jaarsveld, Tessara's head of sales and marketing points out, is only one half of the story. “It's no use combatting food waste and then you create plastic waste. Ultimately we're about combatting waste, whether that means postharvest food waste or plastic waste.”

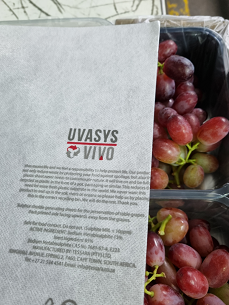

Uvasys Vivo Currently Uvasys, Berrisys and Lichisys (the version for litchis) sheets are mixed plastic, not currently widely recycled.

Currently Uvasys, Berrisys and Lichisys (the version for litchis) sheets are mixed plastic, not currently widely recycled.

“We took note of that and developed a sheet made from a single type of plastic, a polypropylene,” Alwyn says.

“We're quite excited about the kerbside recyclable product range, Vivo and eventually we are migrating all of our products to this range.”

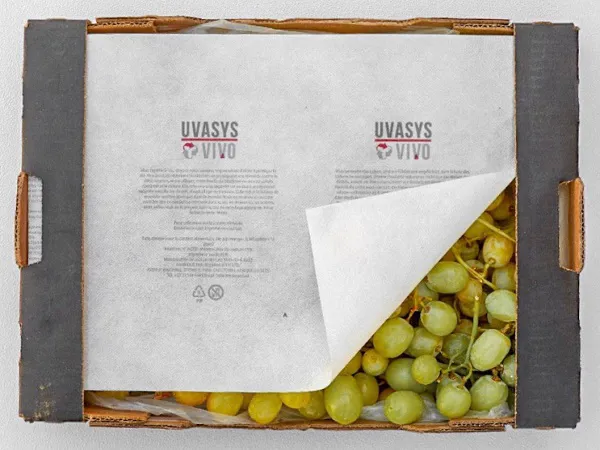

Like the well-known Uvasys generators, Uvasys Vivo's laminated layers contain precise amounts and particle sizes of sodium metabisulfite which, under the correct relative humidity in the grape box, undergo reaction that releases sulphur dioxide gas at varying concentrations over as long as twelve weeks.

After trials in the Southern and Northern Hemisphere, a long-time Tessara client took the leap this past season.

South African grower-exporter Karsten packed table grapes with Uvasys Vivo at one of their packhouses in exactly the same way as they use the conventional Uvasys sheets. The quality upon arrival was perfect, was their verdict.

South African grower-exporter Karsten packed table grapes with Uvasys Vivo at one of their packhouses in exactly the same way as they use the conventional Uvasys sheets. The quality upon arrival was perfect, was their verdict.

Right: DJ Schreuder (Tessara CFO), Adri van der Merwe (Tessara client relations manager) and the CEO of Tessara, Jaco Smit, at a Karsten packhouse with a carton of Crimson Seedless packed with the new Uvasys Vivo generator

“The UK takes it even further,” he remarks, “they not only want something that is recyclable, but also that it should already be made with a certain amount of recycled material.”

They are currently looking into sourcing recycled polypropylene (rPP) for that purpose.

Interest from strawberry growers

”We don't want to use more sulphur dioxide gas than the absolute minimum, even though it dissipates extremely quickly and leaves zero residue. We focus primarily on sodium metabisulphite but we're testing other active ingredients. sometimes you need more than one type of bullet. As food safety regulations become stricter, we need an array of products. Ideally, for every crop you'd also need a range of efficacies.”

Tessara's Berrisys generators, rapidly expanding in use by blueberry exporters (photos supplied by Tessara)

Tessara's Berrisys generators, rapidly expanding in use by blueberry exporters (photos supplied by Tessara)

Soft fruit are very well suited to Tessara's solution, while the need on citrus, waxed with a fungicide, is small. Despite sulphur's preharvest use being allowed in organic farming, the use of sulphur dioxide is currently not allowed on organic grapes.

“Many strawberry and raspberry growers have approached us, but with Covid it has been difficult to do trials and product refinement.”

Tessara also provides grape and blueberry growers in South America and the United States with their generators.

“We find the Chinese market extremely interesting: they consume more or less 50% of the fresh produce on the planet. “We sell a substantial amount of generators for grapes into China and will soon follow suit with blueberries.”

Tessara has expanded its international footprint at a time when COVID travel restrictions have demonstrated the benefit of having expertise on site.

For more information Alwyn van Jaarsveld

Alwyn van Jaarsveld

Tessara

Tel: +27 21 534 4541

Email: alwynv@tessara.co.za

https://www.tessara.co.za/