PalletPlast was awarded the best new end-use product by Petco (a South African plastics industry body supporting the recycling of polyethylene terephthalate or PET), for their fruit pallets manufactured from plastic from the waste stream.

PalletPlast was awarded the best new end-use product by Petco (a South African plastics industry body supporting the recycling of polyethylene terephthalate or PET), for their fruit pallets manufactured from plastic from the waste stream.

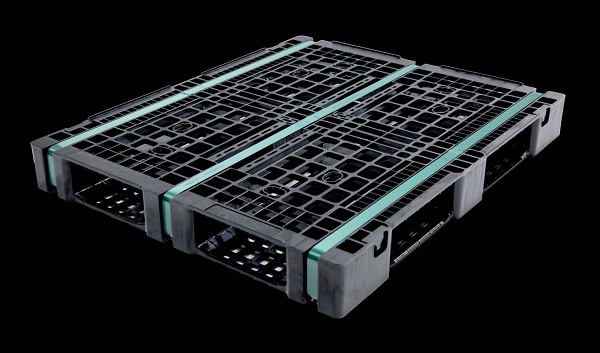

Their plastic pallets are all exactly the same size, and stackable, making them easy to transport, says managing director Christopher Smith.

He notes that around 720 of their pallets can usually fit on an interlink truck, bringing down transport costs.

Plastic pallets are being used more and more in the fruit export industry because of a few pertinent reasons, price and availability of timber being the most prevalent, he says.

“Currently a white block pallet used in the fruit sector is approximately R140,00 [8,000 euros] ex works and the cheapest plastic pallet you can buy (incidentally ours) retails for R220,00 [12,700 euros]. What sets plastic pallets apart from timber pallets though, is that they do not require phytosanitary certificates."

He notes that pallet buyers are not in a crisis, but are very aware of the issues that lie ahead and are putting steps in place to plan accordingly.

Recycling of troublesome plastics

"The growth in the plastic pallet industry has developed beyond our wildest dreams. We've been able to take troublesome materials in the PET industry that are traditionally not recycled, things like barrier layer materials, darker materials, materials that don't derive from bottles, mostly vacuumform and thermaform products.”

Their clients include Berry Astrapak, Polyoak, Premier Pallets, Plastic Ideas as well as large Northern Cape citrus and table grape producer Karsten.

Retailers would do well, he remarks, to start rewarding exporters making use of recycled plastic pallets.

Clients' plastic waste goes into their own pallets

“Our most successful relationships are when we use our clients' waste streams destined for the landfill to make them their own pallets. It is a really rewarding scenario in most cases as it solves problems as well as creates manufacturing opportunities.”

This sort of circular economy is not possible with timber pallets.

While almost impossible to keep tabs on their pallets, given that South Africa's fruit exports are to predominantly first world locations, with well established recycling streams they expect that in all likelihood the receivers of the pallets would recycle them with their other packaging waste (which is entirely possible).

“We really have to get away from the idea of using plastic just once.”

For more information: Christopher Smith

Christopher Smith

PalletPlast

Tel: +27 87 150 7336

Christopher.smith@palletplast.

co.za

http://palletplast.co.za/