Recently, the FDA (Food and Drug Administration) and CDC (Centers for Disease Control and Prevention) in the United States disclosed the founding of a multistate outbreak of E. coli 0151:H7 investigation: the outbreak was linked to leafy greens. However, this is not the first time an outbreak involving leafy greens occurs. According to an IQF machine manufacturer, the use of IQF technology can contribute to food safety,

As the modern lifestyle starts to shift to consuming less meat, salads become the symbol of healthy and balanced diets, says OctoFrost marketing specialist Kerry Hultin. “Despite all the nutrients provided by leafy greens, health and hygiene problems rise with this trend. According to the CDC leafy greens are sometimes contaminated with harmful germs and bacteria, and washing won't remove all germs as they can stick to the surface of leaves and even get inside them. Not to mention that it’s impossible to wash off bacteria like E. coli completely.

"However, cooking leafy greens is an option because ‘the heat kills E.coli and other types of bacteria that can make you sick, as suggested by James Rogers, Ph.D. director of Food Safety and Research at Consumer Reports. At a cooking temperature of 70° C, E. coli and another common bacteria, Salmonella, will be killed. This piece of information opens many new opportunities to processors of frozen leafy products, as frozen food becomes safer to consume than its fresh counterpart.”

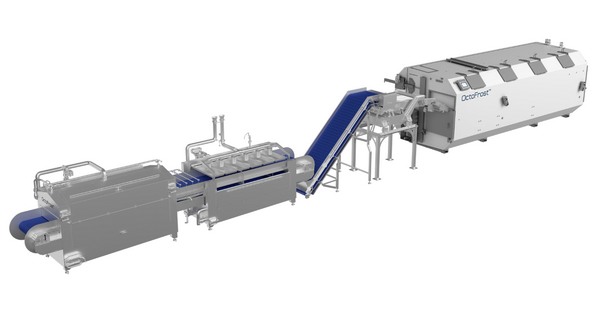

Blanching is a step that can’t be skipped in order to ensure a safe food product, Hultin emphasizes: “Leafy greens such as spinach, considered the most popular frozen leafy veggie from a nutrient perspective, are a great source of enzymes. These enzymes are full of antioxidants which can prevent many health problems such as heart disease and cancer. A quick blanching here halts enzymes' activity in leafy greens, so its nutrients, natural color, and crispy texture are preserved. Temperature control is essential for delicate leafy greens like spinach. In the OctoFrost IF Blancher, a second temperature zone can be added to reduce the final blanching stage's temperature to avoid over-blanching. The rainfall shower system in the OctoFrost Blancher provides five to ten times more water volume, removing dirt and bacteria from the surface of green leaves and steeping leaves for a uniform and quick blanching.”

There is timing in everything, even in IQF processing leafy greens: “Leafy greens should be chilled immediately after being blanched to achieve the best texture and color possible. The OctoFrost IF Chiller is equipped with the same rain shower system; instead, ice-cold water gently falls over the product for a quick and even chilling. The temperature in OctoFrost™ IF Chiller is always kept under the critical 6 C° to inhibit bacteria growth.” Hultin explains.

Leafy greens have layers of leaves and wet leaves are especially easy to stick together. Feeding wet leaves directly into the freezing is highly energy-consuming, Hultin says. “To avoid this high energy consumption and minimize lump formation during the freezing stage, dewatering must be done. Usually, dewatering is done either with a spring-loaded cylinder to lose water by pressing the wet leaves or use a centrifuge to toss the water off. But lumps of leafy greens can still be formed by using these two methods, and these wet leaf lumps will need to be loosened up before freezing. To solve the problem at once, OctoFrost designed a new piece of equipment that separates the dewatered spinach: a tedder that gently rakes and separates the already dewatered spinach.”

“With IQF freezing, microbes' sprouting is stopped. This step double-secures food safety with IQF leafy greens while keeping their shape and nutrients intact. Not to mention that IQF frozen leafy greens have a longer shelf life and are easy to transport without getting spoiled. Processing high-quality leafy green products require the right kind of equipment. In the OctoFrost IQF tunnel freezer, the gentle fluidization generated by the bedplate movement separates the leaves and guarantees efficient and effective freezing. The OctoFrost™ fans have adjustable speeds that avoid the overblowing of light, leafy products into the coil.” Hultin concludes.

For more information:

OctoFrost Group

Email: sales@octofrost.com

www.octofrost.com