The innovative HerbERT drying process has already proven itself at many producers and processors of fruit, vegetables and herbs at home and abroad. The drying system of Austrian manufacture is now available as a large container as well. At Lower Austrian mushroom grower Schwammerlprinzen LLC, the system is now being used for the first time. And with success.

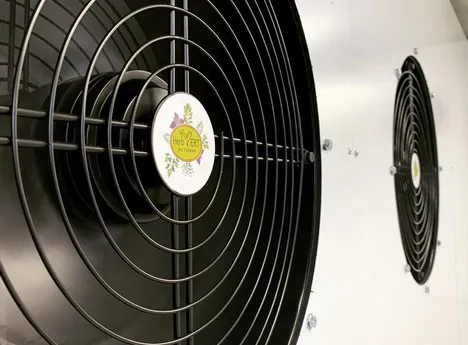

After 24 months of development, the HerbERT container has reached production readiness. "In the last 8 months, we carried out intensive test trials until we had evaluated the optimum coordination of air circulation and gentle drying performance. In the meantime, the system could be successfully installed on site. In the 'big' HerbERT, Michael Doppler and his team from Schwammerlprinzen dry more than 100kg of precious mushrooms within 24 hours," says Bernhard Kastner, partner of the Herb.ERT company.

Regional cooperation

Schwammerlprinzen was founded in 2013 and has been dedicated to the cultivation of high-quality noble mushrooms. The regionally cultivated oyster mushrooms, shiitake and the like are now available throughout Austria at branches of well-known retail chains. Kastner: "The drying container reduces electricity costs - and saves on transport to external contract dryers."

The drying container measures 2.2m x 3m x 2.5m.

The drying container measures 2.2m x 3m x 2.5m.

Practical solution in the fight against food waste

Compared to the existing drying cabinet, the HerbERT 2.0 is significantly larger. "Drying times are significantly optimized, and the quality of the dried products corresponds to that of the premium quality of the Herb.ERT drying oven system, which has been tried and tested for many years." An essential aspect made possible by the use of Herb.ERT: surplus capacities of agricultural products are refined into high-quality dried products."

Low-to-zero food waste is the watchword of the future, Kastner adds. "That's why we are already in contact internationally with tomato growers and vegetable processors who will turn their excess capacity into dried products. Herb.ERT - dry products are preserved with the lowest energy costs, do not require costly refrigeration during storage, and are enjoying steadily increasing popularity among end consumers. Accordingly, our sustainable and practical process contributes significantly to reducing food waste. A unique win-win situation for processors - retailers - and consumers!"

The Schwammerlprinzen headquarters in Perschling, Lower Austria.

In addition, there are considerable sales fluctuations in times of crisis, which is why it is more difficult to plan ahead with regard to marketing. Kastner: "Instead of disposing of surpluses, the longer-lasting dried mushrooms could be brought to market at a later date, in line with market demand."

Further application potential

Similar to the 'Basic' HerbERT system, a wide range of food products can be dried using the container, Kastner points out. "Among other things, our system is used for drying pasta, herbs, vegetables and fruits. Over time, our system has made big waves outside Austria; for example in Switzerland, Germany and Italy. With the drying container, we hope to open up new markets for our business activities. Inquiries for several vegetable drying containers from Kazakhstan, for flower drying in Australia and tea and spice drying in Malaysia have already been received."

For more information:

HerbERT - Der Trockenschrank

Eduard Paschinger & Bernhard Kastner

Dr. Franz Wilhelm Str. 2

A-3500 Krems/Donau

Tel.: +43 (0) 650 4711100

office@herb-ert.at

www.herb-ert.at

Schwammerlprinzen GmbH

Gewerbepark 10

A-3142 Perschling

Tel: +43 2784 203 96

E-Mail: bio@schwammerlprinzen.com

Web: www.schwammerlprinzen.com