When not wind-bound, the port of Cape Town can move 16,000 containers per week, but unfortunately the southeaster wind has been “exceptionally bad” at times this season, notes Terry Gale, chairperson of the Western Cape Exporters’ Club, which represents many in the fruit export industry (fresh produce is the majority of cargo exported from Cape Town).

On late afternoon Wednesday 24 February winds of up to 90km per hour forced a closure of the container terminal, lasting for more than two days until its re-opening the following Saturday. As a result vessels were on average delayed by eight days and many shipping lines are bypassing Cape Town in order to keep to their windows at the subsequent ports to the east or to the north.

High winds accompanied this week's rain over the southwestern Cape, reducing waterside productivity, but today the wind has abated.

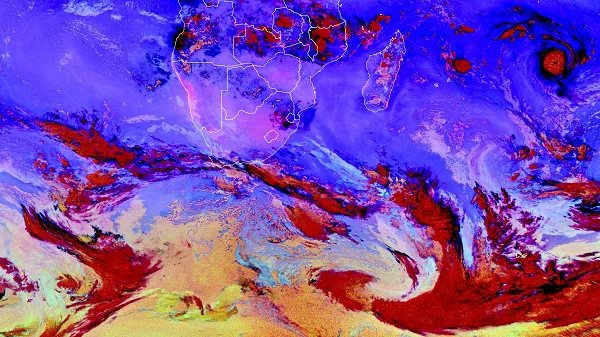

A satellite photo showing the weather that yesterday brought rain (over 100mm in some parts) to the Cape (copyright EUMETSAT)

A satellite photo showing the weather that yesterday brought rain (over 100mm in some parts) to the Cape (copyright EUMETSAT)

Triple whammy at Cape Town Harbour

No import cargo means no empty containers coming into the harbour.

“It’s a major nightmare,” Mr Gale says, but it’s not only Cape Town’s nightmare, he emphasises.

“International trade is a major problem globally. In Cape Town it has been exacerbated by the fact that the wind has been very bad this season, plus there’s the gradual re-opening of the economy as we move to level 1 of the Covid lockdown and factories are re-opening after the festive season. And then we’re also in the middle of the fruit season – it’s a triple whammy, but there are congestion problems at many ports around the world at the moment.”

South African retailers are having to wait two or three week longer for stock coming from the Far East as vessels skip Cape Town.

Cape Town Container Terminal (Copyright: Chris Troch Ι Dreamstime.com)

Calculating the probability of windbound periods

Mr Gale believes there are definitely solutions to the problem of wind at Cape Town, and Glen Steyn from the Western Cape Department of Economic Development and Tourism and convenor of the port task team agrees.

The increase in citrus exports expected over the coming years concentrates the mind on this matter.

Mr Steyn says: “There is recognition of the need for urgent interventions to facilitate cargo flows through the port. Scientific analysis of weather patterns will also be done to formulate predictive models. This could contribute to more efficient planning of container loading and discharging, as well as to mitigation measures against the risk of wind at Cape Town Container Terminal.”

He represents the Western Cape Government at the weekly operational meetings between all parties involved, such as various Transnet operating divisions, government and the private sector, including shipping lines. “The pressure on the container terminal is relentless. The fruit export cycle shifts from one commodity straight into another for almost the entire year and the shared objective is to get this fruit to global markets as quickly and as efficiently as possible so that its quality is preserved."

Ageing equipment

Ageing equipment at both the main terminal (the Cape Town Container Terminal) and at the Multipurpose Terminal is a significant constraint, as pointed out at the port stakeholder workshop in December last year.

Cape Town Container Terminal (photo by Grant Duncan Smith Ι Dreamstime.com)

Cape Town Container Terminal (photo by Grant Duncan Smith Ι Dreamstime.com)

The lifespan of much of the equipment has reached the stage where more breakdowns can be expected, with concomitant higher maintenance costs.

Equipment upgrades and augmentation therefore make economic sense, especially in view of the growth in cargo flows through the Port of Cape Town.

Increased collaboration

The terminal manager is working on opportunities to keep the terminal gate open for longer to even out the peaks in the flow of trucks bringing and collecting containers. He has the support of trucking companies for that.

The new Belcon Inland Terminal offers a rail option to fruit exporters which would reduce truck congestion at terminal gates.

“We collaborate in the port logistics chain,” Glen Steyn adds. “We engage each other on blockages that require urgent attention, such as truck waiting time, vessels omitting Cape Town and fruit exports that have become choked. These blockages are pressing at present and add to the cost of doing business. We all have a common objective, which is to grow the economy and make it easy to do business.”

“We are looking at several options and we realise that we need to think differently,” Mr Gale adds. “We’re all in this together. If we don’t deal with this then every single South African will be affected because of higher costs.”