For processors of onions, carrots or potatoes in small packages from 250 grams to 3 kilos in bags or nets, automation can make the difference. These producers often deliver custom work to their customers and therefore have to deal with a wide range of packaging options or different product carriers. “As a result, a handful of employees are needed every shift to repack these small packages into crates or dollies. In that case, the compact dolly / crate loader from Lan Handling Technologies offers a solution. It is still possible to deliver custom work with one machine,” says Dino Boot of Lan Handling Technologies.

Improved efficiency

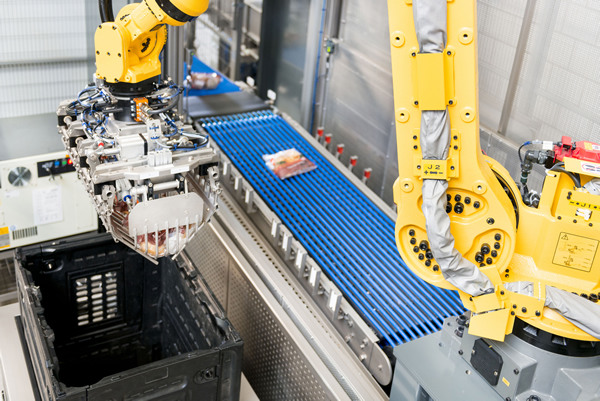

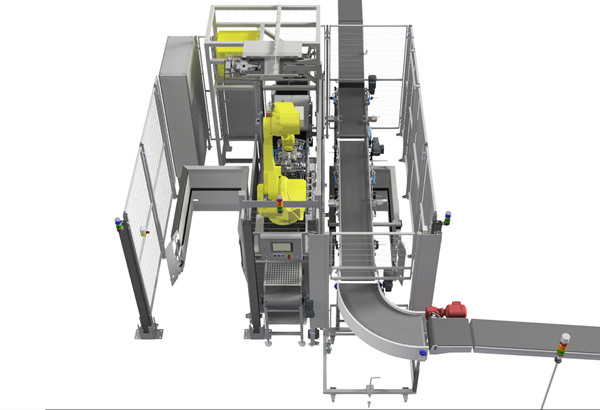

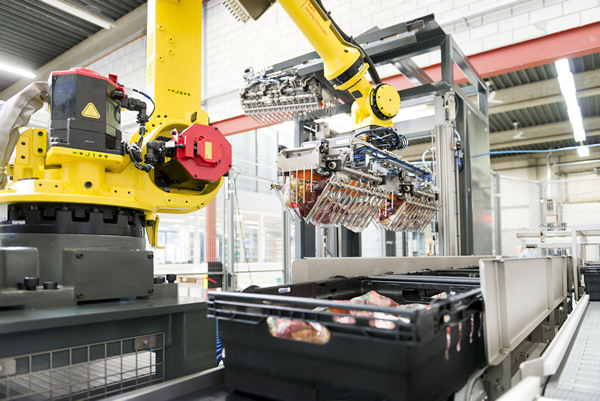

With a capacity of 70-100 products per minute, the fully automatic solution ensures that bags or nets from the pick-up table are placed in a crate or dolly. The dolly / crate loader has a dolly dock and crate transport conveyor available at less than 18 m2 parallel to the pick-up table. Switching to crates is done at the touch of a button. Do you need a different gripper for loading? The robot arm can change the gripper fully automatically in less than two minutes.

Quiet workplace

Dino Boot: “The dolly / crate loader is designed to run continuous production in a safe manner. Where efficiency shoots up, the number of floor movements actually decreases. We can design the combination machine so that you have not just single, but double dolly docks at your disposal. This ensures drastically fewer movements on your product floor. Optimal use of our dolly / crate loader can be achieved with just one operator and / or a forklift driver.”

Onions? Gentle handling

The dolly / crate loader is running successfully at a large German onion and potato processor, among others. “As a result, we know better than anyone the challenges associated with onion handling. For example, onions bounce more than potatoes during internal transport and handling. In addition, onion flakes can negatively affect the uptime of a machine in several ways. ”The Lan Handling Technologies machine is therefore fitted with onion-specific upgrades where necessary for 'gentle' handling and the highest possible efficiency."

For more information:

Dino Boot / Mark de Boer

Lan Handling Technologies

Haarlemmerstraatweg 129

1165 MK Halfweg

M +31 613 15 75 59

E dino.boot@lanhandling.com

www.lanhandling.com/combi