As the labor cost is rising, food processing factories often experience labor shortages. This situation has only grown worse during the pandemic. In addition to the labor shortage, the need for hygiene and food safety has also stimulated the demand for automated food processing machinery.

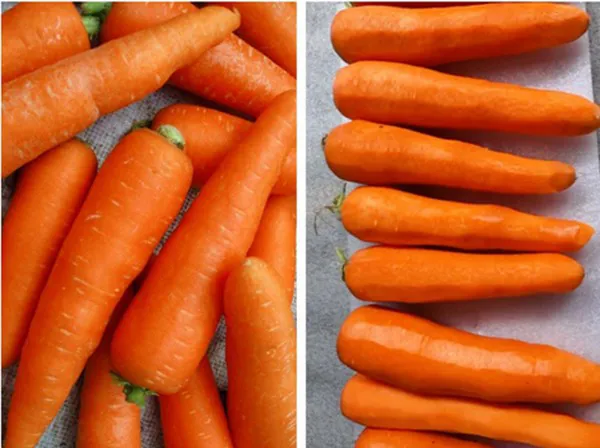

Ningbo Lueon Technologies is a company with years of experience in the research and development of food processing technology. Last year the company introduced an automatic peeling machine with a great price-quality ratio. The automatic peeling machine is suitable for carrots and cucumbers, and other root-like vegetables. These machines help companies reduce labor cost and increase automation.

"We carry out market research in a great many food processing factories while we develop our machinery. We discovered that in many small- to medium-scale food processing factories workers in the preparation area are sitting opposite each other with piles of vegetables in between them. They manually peel the vegetables," explained Valencia. "The working environment is rather cold and damp, and not suitable for people to spend long hours at work. Furthermore, manual peeling adds labor cost and production time to the process. Automatic peeling can improve the production process and reduce waste along the way."

The principle behind this automatic peeling machine is very simple. "The vegetable products are supplied via a conveyor belt, and the peeling blades are powered by atmospheric pressure. The peeling machine has 8 different blades to peel 360°. The blades will adjust their peeling depth based on the shape of the vegetable product in the machine. This guarantees the smallest amount of waste during the peeling process. The automatic peeling machine works very well on carrots, cucumbers, and zucchini," said Valencia.

"The machine can process a maximum of 800 kg per hour. This makes the automatic peeling machine suitable for medium-to-large-scale food processing companies. Only one person is required to operate the machine, and each machine can replace 2-3 workers. The factory can cut down on labor cost and simplify the production process."

When asked about the advantages of the automatic peeling machine, Valencia replied, "the price-quality ratio of Lueon automatic peeling machines is much better than automatic peeling equipment from competitors. This is one of the main selling points. Medium-scale food processing companies in China can see a return on their investment in an automatic peeling machine within 2 years. Another selling point is the size. This machine only occupies roughly 10m2, and the installation process is flexible and convenient." After the Lueon automatic peeling machine was announced, it received a lot of attention from people in the industry. Lueon received great market feedback from clients.

The labor cost continues to rise. That is why automatization in the food processing industry is an important trend. This trend has only grown more significant during the pandemic. Some companies that relied on manual labor too much have had to close down operations because of the measures taken to prevent the spread of Covid-19. The need for automatization is more urgent than ever. This will be an irreversible trend in the fruit and vegetable processing industry, said Valencia.

"Food safety affects everybody's health. Only when we control product quality from the processing factory until the retail market, only then can we guarantee food safety, so that our customers can eat healthy food without worries. Automated washing machinery can improve the efficiency of the production process, but more importantly, this type of machinery guarantees a high level of product quality and food safety in the processed fruit and vegetable markets."

Ningbo Lueon Technologies was established in 2003. Lueon is one of the leading suppliers of automated food processing equipment for the fresh-cut fruit, vegetable, and salad industries. The company team has worked hard for many years to research and develop, design, and manufacture specialized food processing equipment and solutions for the industry. This includes machines for peeling, cutting, washing, drying, and vacuum-sealing.

The company team have now set their sights on the international market to help even more clients enjoy high-quality, fresh fruit and vegetables. Lueon food processing lines and other equipment are already installed in more than 210 factories. These machines process fruit and vegetables for more than 8,000 restaurants and shops every day, including KFC, McDonalds, and Pizza Hut.

For more information:

Lueon Technologies Co., Ltd.

Tel.: +86 (0) 574 65606120

E-mail: valencia.yu@lueon.com

Website: https://www.lueon.com/