After the summer harvest, fruits can be sold as dried fruit as the seasons progress. However, if fruit or vegetables are dried via heat, nutrients can be destroyed and flavorings can be lost. This is why the non-thermal drying of food - i.e. without heating - is particularly popular in the industry. Among other things, there are fans being used for this purpose. A new drying process developed at Empa, using ionic wind, now promises to make the drying of food more energy-efficient, faster and even gentler.

When the rotor blades of a fan rotate, a uniform wind pattern is being created. We are familiar with this phenomenon from everyday life, when we use a fan to cool us down on a hot summer day. An unwanted side effect can be an unpleasant feeling to the eyes, which become drier and drier due to the artificially generated wind. The food industry has been taking advantage of this effect for a long time: Fruit and vegetables are dried in the industry without the addition of heat, because heat reduces nutrients and aromas.

The so-called non-thermal convective drying of food with the help of large fans has a catch, however: drying takes a lot of time and energy. This is why the industry has long been looking for a more energy-efficient method. One technology is based on so-called ion wind. Although this already works on a small scale, it has so far failed when beefing up to an industrial scale. Empa researchers have now developed a more energy-efficient drying system based on ion wind, which is suitable for industrial applications.

Wind, without moving parts

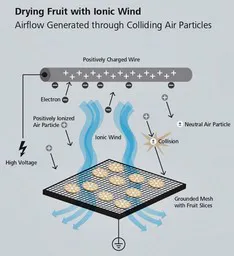

An ion wind is not generated by the rotating blades of a fan. It is created by connecting a metal wire to a positive high voltage source of typically 10,000 to 30,000 volts. This positively charges the wire, ionizing the surrounding air. "Normal" air consists of various gases such as oxygen (O2), nitrogen (N2) or carbon dioxide (CO2). Each of these molecules consists of atoms, which in turn consist of positively charged elementary particles - the protons - and negatively charged ones - the electrons. The electrons are attracted by the positively charged wire, while the much heavier protons are repelled by the wire.

These electrostatic forces ultimately cause electrons to "split off" from the gas molecules. The remaining molecules are now positively charged - or "ionized". The positive ions collide with other air molecules on their way away from the wire towards the grounded collector below and collide with them. This impulse, or rather the particle movement it triggers, then creates an 'ion wind', which is also known as an electrohydrodynamic air flow.

Researchers have attempted to use this ion wind with various approaches for the industrial drying of food - but without remarkable success so far, since upscaling was not possible. Empa researcher Thijs Defraeye and his team from the "Biomimetic Membranes and Textiles" department pursued the idea further and varied several process parameters. First of all, the researchers did not place the food to be dried on a plate as was previously the case, using a grid instead. "Now this is not rocket science, but so far no one has considered this adaptation for drying by means of ion wind," says the Empa researcher.

What appears to be a small  change makes a huge difference: the water can now escape on all sides from the fruit and vegetables. As a result, the ion wind dries the produce twice as fast compared to the ones on the impermeable surfaces previously used by researchers worldwide. Above all, however, the ion wind dries the fruit and vegetables more uniformly on the grid. In contrast to the previously used approaches of electrohydrodynamic drying, the new design is also easier to scale up - and is therefore also extremely interesting for industry players.

change makes a huge difference: the water can now escape on all sides from the fruit and vegetables. As a result, the ion wind dries the produce twice as fast compared to the ones on the impermeable surfaces previously used by researchers worldwide. Above all, however, the ion wind dries the fruit and vegetables more uniformly on the grid. In contrast to the previously used approaches of electrohydrodynamic drying, the new design is also easier to scale up - and is therefore also extremely interesting for industry players.

A new system - from the computer

In further refining their new concept, Empa researchers relied on complex computer simulations. This allows various other adjustments and their influence on the drying process to be simulated virtually. This way, the operation can be optimized "in silico" without having to physically build a new structure each time.

But can the results of the computer calculations also be put into practice? Can the process actually be optimized in this way? In cooperation with researchers from the Canadian "Dalhousie University", a first prototype of the new drying plant was built in their laboratory. Initial tests did indeed show considerable improvements: Ion wind drying is much faster and consumes less than half the energy required by conventional processes. In addition to this, the food is dried more evenly and the nutrients are preserved better. And last but not least, the process can be scaled up to industrial scale relatively easily. Thijs Defraeye's team is currently working with a Swiss retailer to further develop the concept.

For more information:

Prof. Dr. Thijs Defraeye

Biomimetic Membranes and Textiles

Tel. +41 58 765 4790

Thijs.Defraeye@empa.ch

https://www.empa.ch/