This summer, the third generation of Natural Branding machines from EcoMark was launched on the market. The existing process has been significantly optimized, Managing Director Richard Neuhoff explains. "The machine is even easier to operate, can be optimized more easily for customer-specific products and is also easier to integrate into existing production systems, while retaining the flexibility of the EcoMark standards."

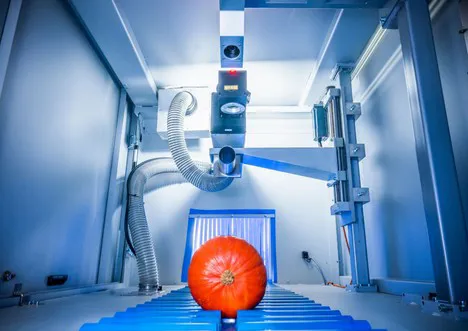

The inside of the Natural Branding machine

The product-optimized adaptations with special optics now also allow natural and gentle marking of larger products such as pumpkins or melons. Neuhoff: "In addition, our latest model is also equipped with special laser heads that can reach speeds of 40,000 mm/s. This is optimal for laser marking of mass products - such as kiwis - and increases both output and laser quality. Maximum productivity is achieved through machine adaptations."

Natural Branding made in Germany

The EcoMark machines are a result of regional cooperation. For example, the machines are equipped with a German laser from a major laser manufacturer whose headquarters in Germany are located in the immediate vicinity of EcoMark LLC. This close development cooperation allows more and more optimizations and possibilities. This is why more and more satisfied customers are relying on EcoMark.

Natural Branding 2.0

The starting point for the latest improvement of the process, which was launched in 2018, was to maintain the full flexibility of the laser process. Even with the product-optimized machines, products with different shapes can still be branded quickly. "The new machine design allows the customer to laser from two sides or integrate it into existing production lines at the same time," Neuhoff says.

In September, the fifth machine specifically for pumpkins was commissioned. The first machine optimized for kiwis was also successfully launched.

Successful use for organic products

The gentle laser process has rapidly established itself in recent years, especially in the organic scene. The latest generation of the machine is also enjoying a good response: "We have already received several inquiries from Germany, BeNeLux and Switzerland and are now trying to make the process better known in other European countries as well."

For more information:

EcoMark GmbH

Richard Neuhoff

Gumbinnenstraße 4

Neuwied 56566

Tel: +49 (0)2631 / 8244-100

Fax: +49 (0)2631 / 8244 29

Mail: info@eco-mark.de

www.eco-mark.de