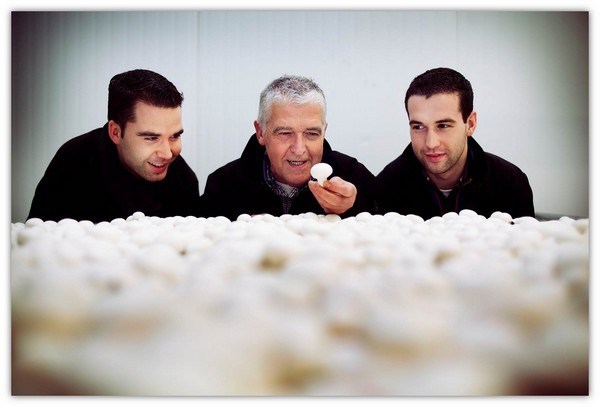

In trade, freshness, via to the shortest possible lines, is vital. That’s especially true for mushrooms. Koolen Champignons in the Netherlands has, therefore, done away with day trading over the years. “In our company, we hardly ever use the term ‘client’ anymore. They’re our partners. So, when I walk into the cell in the mornings, I know exactly who’s getting a great product,” says Teun Kolen. He co-owns the company with his father and brother.

Leo Koolen and his sons Teun and Koen

“No-one’s as quick”

Harvesting and processing mushrooms must be carried out at the highest level. These products must be included in the cold chain as soon after harvesting as possible. Koolen Champignons has set up the process from harvesting to the packaged end product in a specific way. It takes only 30 minutes. “I don’t think anyone else is as fast.”

One of the first things the business did to speed things up was to separate the cultivation and picking processes. “At traditional nurseries, the mushrooms are harvested from racks in cultivation cells. We’ve developed a highly efficient process that is almost entirely automated,” explains Teun. “We added something every year. And after a few years, quite a lot has then happened. The mushroom picking itself is the next step.”

When it’s time to harvest, the pickers don’t go into the cultivation cells. A conveyor belt brings the cultivation containers out. These are placed in a harvesting room, where the pickers are standing at the ready. Here, Koolen Champignons has greatly optimized the selection and harvesting process. Thanks to automation, the pickers cut the mushrooms perfectly. The growth beds are rotated every four hours. In the meantime, the mushrooms can grow as much as another 20%. That’s five percent per hour.

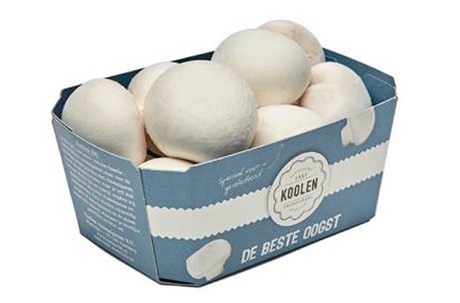

Mushrooms are highly susceptible to mechanical damage. Just touching a mushroom can bruise it. That’s why harvesting must be done carefully, and repackaging isn’t possible. The pickers, therefore, place the mushrooms directly into the clients’ preferred packaging. When the fill weight is reached, the tray goes into cold storage via another conveyor belt. The cold air halts these fast-growing mushrooms’ growth.

It takes five weeks to cultivate mushrooms, and Koolen does so sustainably. They use only water, temperature (regulated sustainably by energy produced from the company’s solar panels and windmills in the nearby Wieringermeer polder), and organic pesticides. When they switch from regular to organic compost, they also switch to organic farming. “Organic compost isn’t only difficult to find; it’s also pricey. That does slow down expansion.”

Locally-grown is an increasingly important factor. “Locally-grown is dangerous if export products drop in value,” says Teun. “There’s more focus on locality in the Netherlands’ neighboring countries than here. But, nowadays, there’s less competition from Poland. Transportation is expensive, and they can sell lots of mushrooms in their own country.”

Koolen regularly revisited the packaging issue. “Maintaining our mushrooms' high quality is the most important aspect for us. But, we’d also like to see less plastic and wastage. Top sealing contributes to reducing waste. We haven’t found solutions in biodegradable containers yet. As long as there are still hungry people in the world, farmers aren’t going to grow maize for packaging.”

“We’re, however, fully committed to using Rpet materials. These mostly consist of recycled substances,” continues Kolen. To prevent food wastage, the company is also trying to find the perfect consumer packaging size. “Exactly what they want is another question. They often find one 250g container of mushrooms to be too little, but two, totaling 500g, is too much.”

Koolen Champignons has two cultivation sites in the Netherlands. The mushrooms in the various cultivation cells are at different growth phases. So, the product is available year-round. The business can supply more than 20 kinds of conventional and organic mushrooms throughout the year.

Cultivated mushrooms, like button or chestnut mushrooms, form the company’s mainstay. Exotic varieties are grown on a smaller scale on organic wood substrate. “We also harvest mini mushrooms as a convenience product for the hospitality industry. These don’t have to be sliced, and they make dishes look lovely. We have wild mushrooms available from September.”

Completely circular since 1981

Koolen Champignons is convinced that Dutch mushroom consumption will continue to grow. “The question is, in what way?” asks Teun. “In most countries, people eat mushrooms in warm meals more often. In the United Kingdom, they start the day off with mushrooms. Dutch people are still Europe’s sandwich lovers.”

Koolen Champignons began thinking about this years ago. They developed a wide range of processed products - from pan-ready and (marinated) assembly products to ready-to-eat meat replacers like mushroom burgers. They develop and produce these in-house. “We started adding more value to our products six years ago.”

“These have become enormously popular, especially in recent years. Mushrooms are excellent base products for meat replaces,” the company owner says. “They’re naturally low in protein. But you can enrich that by adding beans, for instance. The Koolen family agricultural company grows these and other products. These include beets, parsley, pumpkin, tubers, and such. You can make great products from these, which we do ourselves.”

“We develop and produce these products. In this way, the company controls everything. We can offer complete origin and production method transparency. Even the straw our mushrooms grow on comes from the Koolen family. We’re an entirely circular business, actually since 1981 already. But, we only realized that when the term became trendy,” concludes Teun.

“We develop and produce these products. In this way, the company controls everything. We can offer complete origin and production method transparency. Even the straw our mushrooms grow on comes from the Koolen family. We’re an entirely circular business, actually since 1981 already. But, we only realized that when the term became trendy,” concludes Teun.

Voor meer informatie

Teun Koolen

teunkoolen@koolen-champignons.nl

Koolen Champignons

Koolen Champignons

Tel: +31 (0)227 60 30 54

info@koolen-champignons

www.koolen-champignons.com

www.vankoolen.com