More and more companies are trying to diversify their product lines in order to be able to adapt to changes in the market. In an increasingly globalized and ever changing fruit and vegetable sector growers, packhouses and processors are looking for flexibility for their daily operations. ProEx Food LLC. with offices in the US and Germany provides all kinds of machinery – from washing to peeling, cutting and packaging, and even robotics solutions. Marketing director Nick Maglio noticed a focus on multi-purpose solutions among clients in the last year.

“We saw an increase in requests for flexible lines, capable of handling more than one product with little changeover through a multi-function line. Sometimes, it is simply because of a variety of produce that needs to be incorporated in one finished product, as we often see with multipacks or fruit and vegetable salads that consist of a variety of components. Other times, it is due to space and budget constraints, resulting in a need to be inventive with both.”

Regardless of the reasons, ProEx Food prides itself in combining their knowledge and innovative engineering power with global technology partners in order to supply their customers with the means to automated their processes rapidly.

“By reducing barriers to entry for production changeover flexibility as well as options to set new category and new recipe trials, processors equipped with multi-function lines are able to swiftly adapt to changing market conditions, demand and labor availability,” Nick explains. He especially sees the need for this in smaller and mid-range businesses. “Additionally, these enterprising processors will find themselves in the advantageous position of operating with agility – empowered to take on more strategic category and product pivots quickly.”

He compares the idea of streamlining, optimizing and automating processing lines with the rise of the smart phone: “Up until 15 years ago, you needed different gadgets and systems for everything from day planners to business and personal correspondence to encyclopedias to cameras and more. Nowadays, we work with one device that has morphed into an everyday use productivity monster.” Similarly, he encourages processors to consider upgrading their machinery as they would for a phone: “You think about several functions in one device rather than several devices, and this can apply this idea to how companies buy equipment.”

This now holds true to a variety of food processing options, especially in produce. “Many more fresh products are made for grab-and-go purchases. For others, quick shifts between products in the same operating space are crucial to success. Depending on your overall capacity, space and throughput needs, processors have more multi-function line options available to execute these kinds of items.”

The team of ProEx Food at the Fruit Logistica 2020

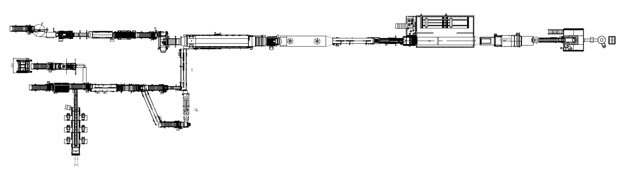

There is a recent case of a very ambitious project in the ProEx Food portfolio: “Our customer wanted to wash, peel, cut, blanch, cool, freeze, sort, package and quality assurance multiple products in a single line. Sometimes, the products would be run independently. Other times, different mixes of the products would be run across several recipes. The initial products and configuration needed to cover carrots, green beans, onions, bell peppers, zucchini and eggplant. Other products would be introduced at a later time, requiring a manual cutting section still integrated into the rest of the line for certain products and experiments. The goal was to mitigate future needs to add more machines. Our co-founder and head of engineering, Daniel Ghadiri, and our engineers created this custom multi-function line that isolated some functions, but came together jointly for blanching, cooling, freezing, optical sorting, packaging and quality assurance.”

Nick and the ProEx Food team are encouraging processors to not limit their idea of machines to individual types of processing: “We are happy to help our clients look for viable full-line solutions for their unique processing needs and challenges. Our big-picture process helps create solutions that are truly optimized for their specific needs. Let us know how we can help, we look forward to helping you in your journey.”

Für mehr Informationen:

Nick Maglio

Director of Marketing

ProEx Food, LLC

marketing@proexfood.com

www.proexfood.com