“Packaging trends for fresh produce often start in Europe and then make their way over to North America,” says Steve Greenfield, Director of Sales & Marketing with NNZ, Inc. out of Atlanta. The core business of this family-owned company is designing packaging options for the fresh produce industry. “We were established in the Netherlands 98 years ago and today, the company has 24 offices around the globe including Europe, the United States, Canada and Africa." Greenfield sees it as an advantage to be European based. “It allows us to identify packaging trends early on and when they have been embraced in Europe, we bring these solutions to our clients in North America.”

NNZ Packaging offers a broad range of packaging products for many different fruit and vegetable items. “We are a packaging designer/consultant and work with packaging manufacturers all over the globe to have unique and sustainable designs fabricated. Not being a manufacturer gives us a unique advantage, as it allows us to be independent. We provide our customers appropriate advice based on their needs,” said Greenfield. In addition, NNZ is also a stocking distributor. “We have seven warehouses throughout the US and two warehouses in Canada that allow us to stock packaging for our customers and ship it out quickly,” he said.

Move from bulk to packaged

Not only does NNZ bring innovative packaging solutions to North America, the company also sees opportunities to grow the segment. “At the moment, about 20 percent of all produce sold in the US is packaged and 80 percent is sold in bulk. In Europe, it is opposite with 80 percent of produce being packaged. This shows the opportunities in the North American market.” Due to COVID-19, the company is already seeing a migration from loose to packaged product.

NNZ’s niche is the design of sustainable packaging. “We ask our customers to rethink their packaging using a fact-based packaging route.” Four variables determine the definition of sustainability: source reduction, recyclability, footprint of materials (carbon footprint, fresh water usage, and energy usage) and food waste. Taking these variables into account, the company prefers the use of mono-materials that are recyclable. Paperboard trays for instance look more earth friendly, but sometimes recyclable non-biodegradable plastics are better for the environment. An example from Europe is the move to mono polymer pouch bags. “They may not look as pretty as the laminated pouch bags, but because of the use of single substrate, these are fully recyclable.”

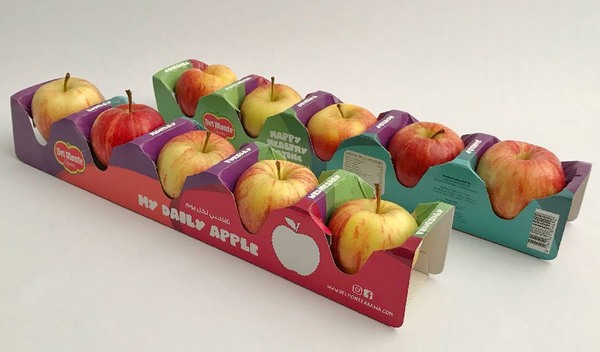

AppleSet packaging.

AppleSet packaging.

Popular types of packaging

One type of packaging that shows great interest in Europe is the AppleSet. It is a paperboard tray that can hold about four to five products. “It’s a nice and different stackable display and we are starting to see interest for it in the US,” mentioned Greenfield. Contrary to what the name may suggest, AppleSet trays are often used for kiwis, peaches, and plums. There is a trend towards paper packaging as it is perceived more sustainable than plastic by consumers. An example is the Paper Vento, which is also making its way to the United States. This paper bag with a vent window of compostable mesh is often used for potatoes. Unique in the design is the fact that it is heat sealable.

Paper Vento packaging for potatoes.

Paper Vento packaging for potatoes.

Greenfield realizes sustainability comes with a price and there is a ceiling in terms of what companies are prepared to pay for it. “My experience is that companies are usually inclined to buy it if it is less than two times more expensive compared to conventional plastic packaging. However, if it is no more than 1.5 times more expensive, there is a higher adoption rate.”

For more information:

For more information:

Steve Greenfield

NNZ, Inc.

Tel: 800-634-7666

sgreenfield@nnzusa.com

www.nnzusa.com