Ensuring that a product arrives in stores with optimal freshness and is able to hold onto this freshness even after it has been purchased has always been one of the most important goals for the fresh produce industry. Extending a products’ shelf-life means less product loss, less food waste and more efficiency in the supply chain. Liquidseal is a product that helps extend the shelf-life of fruits with a hard shell, such as avocado, citrus, mango and papaya. Now, since March 2020, melons can also be treated with this post-harvest treatment.

Reducing food waste in the supply chain

Liquidseal has been on the market since 2017-2018 and is a chemical free post-harvest treatment that can be applied by spraying or dipping directly after harvest. “The specific characteristics of the product enable us to cut product wastage between 30 and 40% as well as reduce the need for pesticides and plastics. It is also compatible with organic fruit, and at this moment the Liquidseal recipes are compliant as Food Contact Material with all EU and USDA regulations including the use on organic fruits (both KIWA and C.A.A.E. certified),” says Victor Monster.

He adds: “With a rapidly growing global population, there is an increasing demand to actually consume what we produce and prevent waste as much as possible. Liquidseal can make a major contribution to reducing food waste in the supply chain and have a positive impact on eliminating food shortages – as well as reducing the need for plastic packaging during transportation. It also provided greater flexibility in the logistics and reduces supply chain costs.”

He adds: “With a rapidly growing global population, there is an increasing demand to actually consume what we produce and prevent waste as much as possible. Liquidseal can make a major contribution to reducing food waste in the supply chain and have a positive impact on eliminating food shortages – as well as reducing the need for plastic packaging during transportation. It also provided greater flexibility in the logistics and reduces supply chain costs.”

Liquidseal for Melons now available

Now melons, specifically Galia and Honey Dew melons, can also enjoy these advantages. “Each type of fruit has its own specific characteristics and challenges to maintain or extend their shelf life and quality throughout the supply chain. On a daily basis, Liquidseal’s laboratory is working on developing formulas which are resulting in reduction of a product’s weight loss, reduced mold development and cross contamination for the different types of fruit. By launching Liquidseal for Melon into the market, all growers, importers and packers of melons now have access to a customized, cost-effective and sustainable post-harvest solution,” Monster explains.

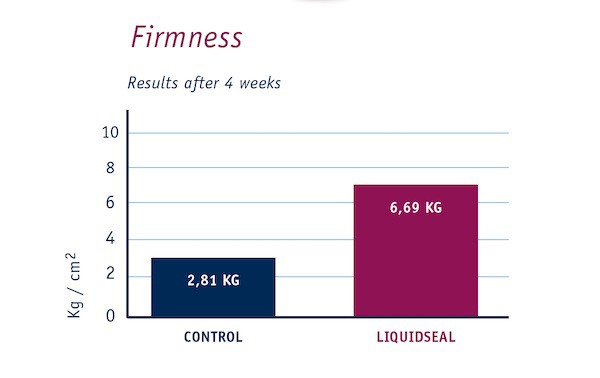

In a trial, melons treated with Liquidseal outperformed the control group by maintaining their firmness to 6.69 kg/cm2 compared to 2.81 kg/cm2. “The current formula also proves to be functional on melons and yielded 2.61% less weight loss, which is an overall reduction of weight loss of about 24%,” Monster says. The product will be introduced where melons are produced, such as Africa, Asia, and South and Central America.

Liquidseal’s research and development team is currently working on extending the line to also include post-harvest treatment for pineapple and bananas. “Within the near future, introduction for these fruits can be expected,” Monster concludes.

More information:

More information:

Victor Monster

Liquidseal Fruits BV

Email: vmonster@liquidseal.nl

www.liquidseal.nl