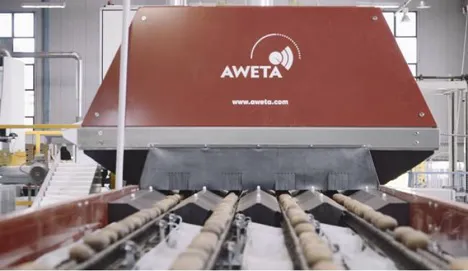

IQA-InScan Pulse is the Aweta sensor for kiwi selection based on the organoleptic characteristics of each single product that determine its flavor and consistency: these are fundamental elements for operators to determine when, to whom and at which price to market their products.

Until now, technology was focusing on quality selection to eliminate soft kiwis because they not appreciated by end consumers. Consistency i.e softness is an important parameter, but in parallel there are other internal characteristics essential for kiwi flavor, especially for the yellow-fleshed varieties.

IQA-InScan Pulse is the latest development in Aweta technology for in-depth analysis of internal characteristics.

Different pulp colors detected by IQA-InScan Pulse

Different pulp colors detected by IQA-InScan Pulse

IQA-InScan Pulse: how it works

It is a spectrophotometric sensor for the on-line detection and measurement of the near infrared reflectance emitted by each kiwi passing under the sensor on a fruit carrier. This technique allows a rapid and precise prediction of the analytical characteristics of substances inside products and therefore on its relevant nutritional parameters. These results are obtained by means of NIR technology that detects and interprets the near infrared light reflected by each single product, according to specifically set evaluation parameters.

IQA-InScan Pulse: what can it see?

IQA-InScan Pulse can select by:

- Pulp color

- Brix

- Dry matter

- Ripeness

- Chlorophyll

The system detects the content of dry matter, chlorophyll and the sugar content (Brix degree). From these values other parameters can then be calculated. The determination of the dry matter content is fundamental because it is the parameter that includes soluble substances (sugars and acids) and insoluble substances (structural carbohydrates and starch) and, above all, it does not change during post-harvest working processing.

With the combination of the various data collected, products can be classified with great accuracy, thus obtaining homogeneous batches and identifying niche products, which in turn enhance positive economic results. The accuracy of the system is particularly important for products when sorted coming out of storage cells.

IQA-InScan Pulse: advantages

- Monitoring of product quality in real time

- Reduction of destructive tests that provide weak statistical information

- Extra decision-making tools for the management / marketing of the stored product

- Sorting out of niche products

- Homogeneous batches of stored products on the base of external and internal quality

- Reduction of sorting and operational costs of sorting plant or centre

- Full product in-house traceability

- Marketing-oriented product evaluation

- Final effect: satisfied customers

IQA-InScan Pulse: contacts

Your products contain all the important information that make your success possible. IQA-InScan Pulse sensor reads and analyses these data relating them to the characteristics that match consumers’ expectations.

More color, more flavor, more added value!

Contacts:

Aweta

Norman van der Gaag - email: sales@aweta.it

Justin Taylor - email: sales@aweta.it

Massimiliano Severi - email: sales@aweta.it

Web: aweta.com