Recycled PET (rPET) is increasingly used more and more for the production of fruit and vegetable trays; as circular packaging is key. The metal filters used in the production process in large manufacturing lines have to be changed daily, sometimes every shift and cleaned of debris.

"To clean these filters, our customers in the packaging industry use  our particularly gentle and environmentally friendly vacuum pyrolysis technology," stated Virgilio Perez Guembe, an expert at thermal cleaning at SCHWING Technologies. This fully automated process is much faster than the long manual procedures and only takes eight to ten hours. "Our VACUCLEAN systems are cleaned quickly and in a single step, saving time and labor," emphasized Perez Guembe.

our particularly gentle and environmentally friendly vacuum pyrolysis technology," stated Virgilio Perez Guembe, an expert at thermal cleaning at SCHWING Technologies. This fully automated process is much faster than the long manual procedures and only takes eight to ten hours. "Our VACUCLEAN systems are cleaned quickly and in a single step, saving time and labor," emphasized Perez Guembe.

Short cleaning times for filters contaminated with rPET

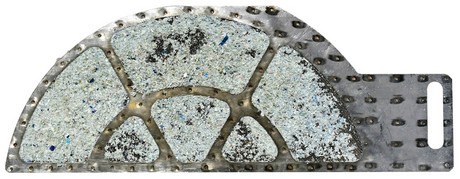

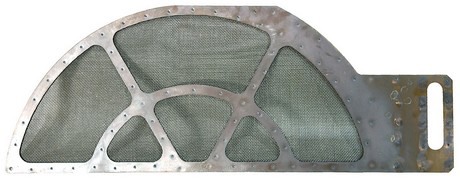

Some examples of these applications are metal filters of approximately 85 x 35 cm, which are used in the process of producing fruit and vegetable trays. The producer, a Spanish packaging manufacturer, works with rPET. The company has to clean its filters daily and uses SCHWING's vacuum pyrolysis technology and special cleaning skills. Technical factors, such as the duration of the individual cleaning, the vacuum atmosphere, the exact temperature curve and the maximum temperature of the entire process, were specially adapted to the filter systems and rPET of this user.

The VACUCLEAN thermal vacuum cleaning system from SCHWING Technologies

The ecological cleaning process in the vacuum pyrolysis system

Cleaning is done in an electrically heated vacuum cleaning chamber, the temperature of which is measured directly on the filter. "The equipment warms up slowly and gently to allow a large portion of the rPET to melt and come out. The actual pyrolysis process, which breaks down the remaining polymer, only starts at about 440 degrees Celsius," stated Perez Guembe. The remaining carbon is removed by a subsequent oxidation phase at about 450 degrees Celsius. All this process is fully automated and leaves almost no residues.

Metal filter contaminated with RPET before and after cleaning

Digital integration of the VACUCLEAN cleaning system

To digitally optimize the cleaning process, the SCHWING development team has added several new components to the vacuum thermal pyrolysis system. In addition to a new touch panel with internet connection, these digital modules include an internal data connection system and equipment's digital documentation in the SCHWING cloud. Other technical innovations include a fully electronic measurement of the flow for the catalyst air supply, a process signaling lamp, and a revised fault alarm concept.

Process data is entered into the touch panel, which has a network connection

For more information: