ProEx Food has set its sights on 2020 as the year in which robotic automation solutions will be a key focus of its market awareness, solution engineering design and sales strategies. “Our foundational products and service build upon food processing equipment, mainly in sweet corn and green beans; making proprietary enhancements on our in-house products and introducing global options to our portfolio. We keep working to ensure we meet customer needs for organizations of all sizes from both our US and German offices. That means we are quickly evolving to cover additional food verticals, mostly in fruit and vegetable applications. We aim to also help automate more aspects on our customers’ lines”, says Ross Lund, CEO at ProEx Food.

Daniel Ghadiri and Ross Lund

He continues, “As we have become a more comprehensive solutions integrator, our customers have been asking us to help with process and design engineering, conveyors and platforms and control system integration, which is helping them become more operationally efficient. We keep innovating for our customers and always ask what else we can help with. The response is common. Our customers still have persistent labor shortages and feel this is holding them back from growth, as they still need people to perform certain tasks via relatively manual steps. Not only is staffing and retention an issue, but product quality is known to reduce over the course of a shift. These customers ask if we have additional ways to help them reduce their dependence on labor to execute and deliver their end products, while ensuring their quality doesn’t slip. We answer with the ProEx Food robotic applications that are available.”

With the desire to help processors improve efficiency while solving for these labor shortages, ProEx Food constantly researches new tools to add to their designs and portfolio products. The goal is to find innovative solutions that are both attainable and reliable without adding to return realization timelines. They know their customers won’t consider investment in an alternate solution unless both operational efficiency and throughput also improve. As the answer has become apparent in robotics, ProEx Food’s lead engineer also works to ensure that modern tech is ready for fruit and vegetable processors.

Daniel Ghadiri, CTO & President at ProEx Food explains: “First-gen units that people had experimented with in the past were harsh on product. The technology wasn’t ready then, and there is a false perception that this is still the case. Knowing this, we have a robust qualification process to ensure any products we add to our portfolio and include in our proposals meet ProEx Food brand standards. As we meet with potential partners, we challenge them to live test equipment and prove to us that their products are ready for real-world applications. The units we offer are more precise and gentler, while stronger, than human hands. They also repeat the processes without tiring.”

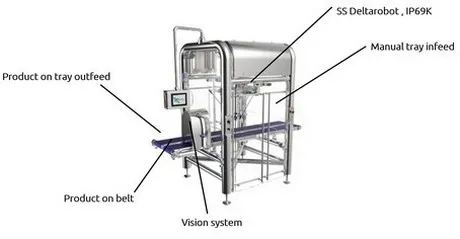

Beyond product handling and output quality, ProEx Food knows that even the best solutions on paper have to be feasible for use in a live production environment. Ghadiri continues, “My background is in engineering, and I work with our design staff to ensure our solutions are viable as an add-on to existing lines or for complete line builds. In either application, we are aware of both space and material restrictions. Our robots are usually compact to ensure they fit into an existing space. We also ensure most components, especially those that interact with product, are made of food-grade materials and run on energy sources that are available in a processing plant. That’s a place where we excel – ensuring these solutions are immediately able to be implemented.”

ProEx Food partners with suppliers that have experience in food production for their automation solutions. Several currently available products started out for applications in different food verticals and have been jointly reengineered and optimized to work with the product lines ProEx Food specializes in, including fruits and vegetables. “ProEx Food is now including robotics, often delta pick place, in more and more installs”, says Lund.

John Swanson, Customer Solutions Manager at ProEx Food, has first-hand experience in the impact labor shortages has on profitability. As he puts it, “In the 40-plus years that I’ve worked in manufacturing, we’ve gone through all kinds of operational transformations all revolving around increasing profitability. The robots today are the next level, as they finally create an option for operational leaders to achieve new levels of operational efficiency while reducing labor. Our customers are excited to hear more about this, and we have tools to help them calculate the payoff periods in their investment. It’s often faster than they’d think.”

In 2020, ProEx Food is planning to make sure more customers are aware of the breadth of robotic options in their solution portfolio. They brought one of their robots to Pack Expo and displayed video of fully automated lines and robotics at their MWFPA booth in 2019. Nick Maglio, Director of Marketing at ProEx Food explains “We spent 2019 validating the market at US-based tradeshows and showcasing our initial installations. The response has been very positive from our customers who have stopped and watched our robots in real-life action. Now it’s time to ensure the rest of our customers worldwide become aware. We’re bringing a delta robot to Fruitlogistica 2020, this February in Berlin, Germany and are planning to attend a few more shows over the course of the year. We’ve also started to restructure and add content to our website and distribute more product updates to our customer database. We plan on being aggressive here over the next year, ensuring our customers are aware that we can help solve for their labor issues today.

Come visit ProEx Food at the Fruit Logistica 2020 in Hall 9, booth E-09.

For more Information:

Nick Maglio

Director of Marketing

ProEx Food, LLC

m: +1 414-324-0337

nickmaglio@proexfood.com

www.proexfood.com