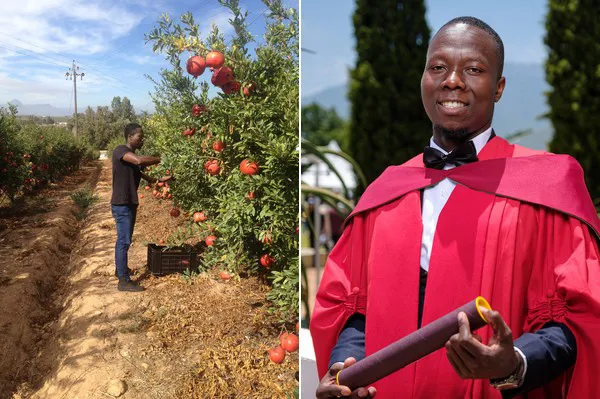

Sometimes one has to think outside the box to solve a problem. This is exactly what Dr Matia Mukama from the Postharvest Technology Research Laboratory at Stellenbosch University (SU) did when he designed new multi-layer ventilated cartons that could soon help increase pomegranate export volumes per unit container, reduce packaging material needs, lower energy costs for cooling pomegranates and keep them fresher for longer.

As part of his doctorate in Food Science, Mukama came up with the new design to help improve the overall performance of ventilated packaging in the pomegranate industry. Globally, this is the first time that a multi-layer ventilated carton has been designed for the handling and export marketing of pomegranates.

Mukama, who hails from Uganda, received his PhD at SU on 12 December 2019. In addition to this achievement, he finished second at the 2019 South African FameLab science communication and public speaking competition held in Durban in May this year.

His research forms part of the South African Research Chair in Postharvest Technology’s programme on “Next Generation Ventilated Packaging of the Future” led by Prof Umezuruike Linus Opara, the incumbent of the mentioned Chair. Prof Opara and his colleague, Dr Alemayehu Ambaw Tsige, supervised Mukama’s doctoral study.

Mukama used computer-based techniques to redesign the vent holes of pomegranate fruit cartons to improve airflow and cooling performance in stacks; and to design new ventilated corrugated paperboard cartons that hold pomegranates in multilayers to improve cargo density, space and material utilisation. The best performing virtual prototypes were then physically manufactured and experimentally evaluated to meet industry standards.

“The new multilayer carton design uses comparatively less cardboard material, allows for a lot more pomegranates to be packed in a shipping container, cools pomegranates more uniformly and faster, and leads to savings in packaging material. Together, these allow for better utilisation of both storage and shipping container space, save trees, and save energy required to cool and maintain the required fruit temperature,” says Mukama.

“Tests on the performance of the new multi-layer carton design showed that over 1,8 tonnes more pomegranates could be loaded into a shipping container compared to the current single layer carton design.

“In a standard refrigerated 12 m (40 ft) container loaded to capacity with 20 pallets of fruit, the new multilayer design will hold 4 800 more pomegranates (240 cartons) compared to the current carton used in industry. Based on the volume of fruit exported from South Africa in 2018 and assuming sea freight, the new multi-layer carton would require 26 less refrigerated containers than current commercial cartons.”

Mukama points out that with multi-layer cartons about 15 152 less refrigerated containers would be required globally to handle fresh pomegranates. This would also help to reduce greenhouse gas emissions associated with refrigerated transport and cooling, he adds.

Mukama says the findings of his study highlight the need for proper carton vent design and vent-hole alignment in stacks of fresh fruit during postharvest handling, storage and refrigerated transport.

“This is important because the main limitation of single-layer pomegranate cartons is the improper vent-hole alignment when they’re stacked in pallets. This creates hot air zones during forced air cooling, thereby delaying cooling, and resulting in non-uniform cooling of fruit inside the carton. Both inadequate cooling rate and improper temperature along the supply chain reduce the quality of pomegranates.”

As to who will benefit most from his research, Mukama mentions those in the pomegranate industry, consumers and the environment.

He says they will now patent the new multilayer design and also conduct extensive commercial export trials.

For more information:

Martin Viljoen

Stellenbosch University

Tel: +27 21 808 4921

Email: viljoenm@sun.ac.za