Graco and Schoeller Allibert announce a cooperation introducing a global solution for both the container and the unloading systems for tomato paste and fruit juice. Combining Schoeller Allibert's new foldable intermediate bulk container (IBC), the Combo Fructus and Graco's SaniForce bin unloader offers a safe, efficient and hygienic solution for the storage, transport and unloading of tomato paste, fruit preparations and juices.

The Combo Fructus®: Performances and safety first

The Combo Fructus® is works for tomato paste and fruit juice main processing companies in the USA and Europe by offering the best performances of the market: its strong and durable double wall structure enables a 1500kg unit load, a stack load of 8000kg and a 3200kg dynamic load. When stacked, this IBC offers maximum safety thanks to its T-shaped locking system and the double wall water-tight lid allowing strapping. Anti-slip plugs coming under the smooth base with reinforce handling safety. Not only is this safe to handle but it’s above all water-, dirt-, bug tight and needle proof, making it a safe IBC for the tomato paste and fruit juices.

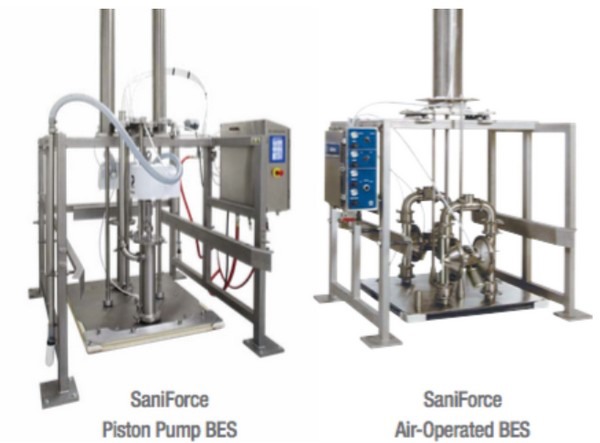

Graco SaniForce Bin Unloader: a fast and efficient unloading system.

The SaniForce Bin Unloader is a clean method to unload materials from 1192-liter containers, eliminating manual scooping or bin dumping. Without contaminating, diluting or heating the product, the unloader achieves up to 99% evacuation rates of high viscosity ingredients. Once the Combo Fructus is placed below the unloader, the ramp plate and pump is lowered into to the container, just above the product. The seal is inflated to hermetically seal of the bin. When the pumping starts, the product is moved out of the container and the plate with inflatable seal travels down into the container, scraping the product from the sides of the container. The product waste is minimal and the transfer perfectly hygienic.

East to clean, time saving and cost effective

Both the Combo Fructus and SaniForce Bin Unloader are automation-friendly which allows saving in labor and increases the process

efficiency. The combination of the products saves time and energy during cleaning thanks to the flange connections at the unloader and the fast-drying design of the IBC. Up to 7 folded Combo Fructus' can be pilled in a standard truck, reducing logistic costs and the environmental impact. Maximising the life span is also a way to increase its cost-effectiveness, that's why all parts can be replaced, as well as the skids thanks to a unique and innovative bayonet fixing system. Schoeller Allibert ensures the complete recycling of all its products such as the Combo Fructus, which lowers environmental impact. The SaniForce Bin Unloader has up to 99% evacuation rate reducing waste and saving water. Overall, the combination of the Combo Fructus and the SaniForce Bin Unloader will reduce a facility's environmental footprint.

For more information:

Isabelle Dejeux

Shoeller Allibert

Tel: +33608169128

Email: isabelle.dejeux@allisonpr.com

www.schoellerallibert.com