For asparagus producers, there is a peak of around three months every year for the processing of their "white gold". The asparagus must be harvested, packaged and transported in these three months. This process is time consuming, but Cyklop BV has developed a faster and more environmentally friendly solution. The rubber band method Strepper® is already used by various growers, such as Fruchthof Schindler in Warpe.

The asparagus of the Lower Saxony farm is packed in a plastic bag, labeled and stowed in boxes. These boxes are ready for sale on the way to the supermarket where the product is scanned at the cash register. The labels printed with barcodes differ according to the type of asparagus (green or white) and can be printed with much more information. In addition, employees should be able to easily adjust the variable print data and/or change the labels.

Clemens Mertens is already on board with the new solution. The vegetables of the enterprise bear the "Nienburger asparagus" quality label.

Reduction of plastic film

The Schindler farm has long had the desire to reduce the consumption of plastic at the customer end, and to accelerate the packaging process. Cyklop was asked to improve this process. It is important that labels and print data can be easily changed, that the asparagus is packaged quickly and film consumption is drastically reduced.

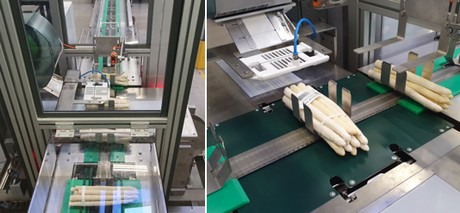

Last year, the family of producers opted for a Elasto binder with label printer. The Strepper® process from Cyklop BV combines asparagus with two thin rubber bands. The closed rubber band does not deform the product and leaves no traces or damage. A label is attached to a rubber band. The label and the print data are easily convertible.

Daily creation of labels

Within a year of its first use, the process was already profitable. The combination of Elastobinder with label printer means that the labels no longer have to be pre-printed, but are printed immediately, explains Clemens Mertens, co-owner of the fruit farm Schindler. "Working with the Elastobinder, we can now create the labels on a daily basis. We can also easily switch between green and white asparagus."

Furthermore, the process is faster because the bundling and labeling in a single operation is done. "In the past, one worker packed the asparagus in a plastic bag and then labeled it by another employee, and now these two steps have been combined to save the plastic bags," says Mertens.

Machine demo at this year's Interaspa in northern Germany.

Significant plastic savings

For a whole season, Früchtehof Schindler staff have been working seamlessly with this solution, and the order for further automation has already been placed. "Our end customers and supermarkets are very happy with the savings on plastic bags," says Mertens with satisfaction.

Visit the company at the International Asparagus Days on October 29th and 30th in Angers, France (Amphitea Hall, Stand 60) or ExpoSe (Hall 1, B08).

For more information:

Cyklop Nederland BV

Benjamin Franklinstraat 5

8013NC Zwolle, Niederlande

T: +31 38 4675800

info@cyklop.nl

www.cyklop.nl

Früchtehof Schindler

Warpe 21

27333 Warpe

Tel.: 05022 8171

E-Mail: info@fruechtehof-schindler.de

www.fruechtehof-schindler.de