Frozen food company d'Arta has been working collaboratively with key suppliers to address sustainability issues and its needs for a flexible sorting solution that is capable of handling very high capacity throughputs of frozen vegetables with no loss of efficiency.

The company’s slogan – It's a green green world – relates to the fact that sustainability is a fundamental part of the way in which the company manages its daily activities. In common with all d’Arta operations, the UK-based CO2 neutral Yorkshire Greens facility is a joint venture; in this instance with GWE Biogas and Swaythorpe Growers, a 40-strong farming co-operative. This collaboration enables waste from harvesting and production processes to be transformed into sustainable energy which is used in the plant to ensure a greener product with the lowest possible carbon footprint.

d’Arta’s co-operative ethos extends to its equipment suppliers. The company has a longstanding, and mutually beneficial relationship with Bühler Group. For many years the two companies have worked collaboratively to solve the challenges typically faced by the fresh and frozen foods sector and to help improve the efficiency of optical sorting equipment to ensure 100% food safety.

“Our relationship with d’Arta remains strong because both companies are willing to communicate and share information at all levels across the business,” said Stefano Bonacina, Global Head of Market Segment Fruit & Vegetables at Bühler Group. “We work with d’Arta at a European level and have helped throughout the company’s expansion into Portugal, the UK and most recently into Italy.”

Commenting on the collaboration, Pieter De Backere, co-CEO at d’Arta, said: “Some time ago we were given a demonstration of the prototype SORTEX FA2 and its capabilities exceeded our expectations. This resulted in us ordering two of these optical sorters for a packaging line in our facility in Portugal.”

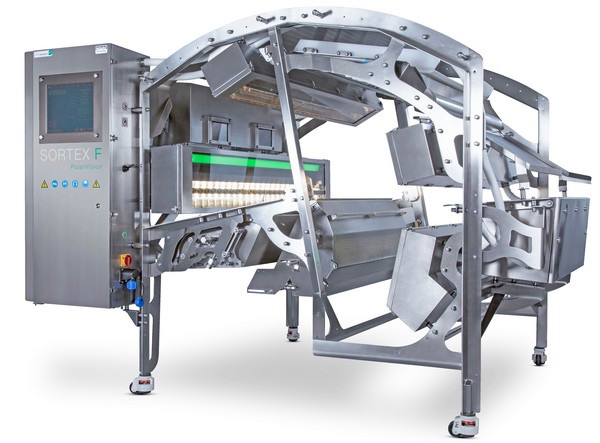

The hygienically-designed SORTEX F range has the ability to accurately detect even subtle colour defects, extraneous matter and foreign materials in frozen fruit and vegetables. The SORTEX FA2 is able to handle processing capacities of up to 14 tonnes per hour.

“Our good experience with the SORTEX range led us once again to turn to Bühler when we needed a sorter with more processing capacity at our Yorkshire Greens facility,” continued De Backere.

In conclusion, De Backere said: “We are convinced of the quality of Bühler equipment and this is a much more important consideration for us than cost. We take a long-term view when it comes to partnership arrangements with our suppliers because we want to ensure that equipment technology will develop alongside our changing process requirements. We have absolute confidence in our partnership with Bühler and will continue to work with the company to find the best sorting technology solutions as we update plant and equipment at our new Italian facility and carry out a project for 3 new FA2 machines in our new packing department in Belgium.”