Major fresh produce post-harvest technology company, Compac says its new fresh produce sorting and grading technology is no longer about simply replacing labour costs but adding value to each load of fruit.

After recently visiting 19 of the company's customers in South Africa, CEO Ken Moynihan said that not only were operational costs lowered by removing all of the sorting labour, but the technology has increased the value of premium produce.

Jacinto Trigo and Ken Moynihan

"Consistently you get between 12-18 per cent more export Class I fruit when the machine is making the decision," he said. "This is at the same time as getting less rejections in the market from customers. So, it's a more consistent and reliable product. Our customers are interested in using the data generated by our technology and asking how they are going to push that information back to the farm to make farming more efficient also how they are going to move that information forward to the supply chains?"

Emerging markets (Colombia)

“We supply systems which can operate with a range of different fruits. Our systems can be built up over time, which is crucial in an emerging market such as Colombia, where people are investing a lot of money at the start in just growing their fruit. It takes time to start earning money on it and they want the ability to add to their packing system as the production increases in terms of both volume and sophistication. The challenge is that investments are 10-15 years and you don’t want out grow your investment in 2 years. It is critical in the design of our solutions that they have that room for growth, and it is a standard conversation we have with our customers that not everybody has to have everything at once and that modules can be added.”

Mr Moynihan said that to prepare for the future, changing technology and markets needs it is important to have an open mind, it is impossible to design machines for the next 15 years, “A good example of this is in packaging, we can set up a whole system for one kind of packaging then the retailer decides they want a different type of packaging, so the whole thing has to change. We design with that in mind so that aspects which are most likely to change have some degree of flexibility in them.”

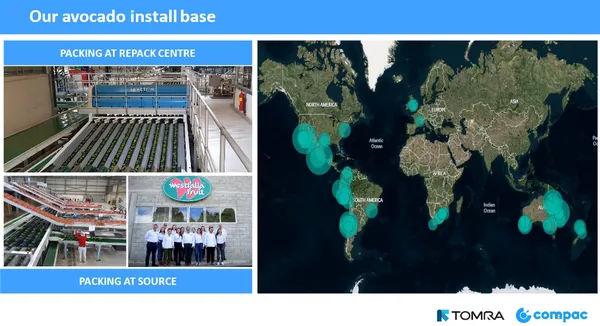

“Our very first trip to Colombia was in 2014 to understand the market,” explains Jacinto Trigo, regional Director LATAM. “We waited until the market had reached the right point before entering and in the last 18 months have delivered three systems including one for Westfalia. We have a partnership here with a company, so we send all the technology and they integrate it into packlines here. We also have our own people in place here as in other parts of the world."

The biggest concern in Colombia is logistics, “How are people going to get the products to market with the existing road systems? But people operating here come from experienced growing countries and I think the government will implement improvements very soon. As for the supply chain, lot of companies are building coldstores and every month there is another announcement by a big company that they are investing here and bringing their expertise in to help the market.”

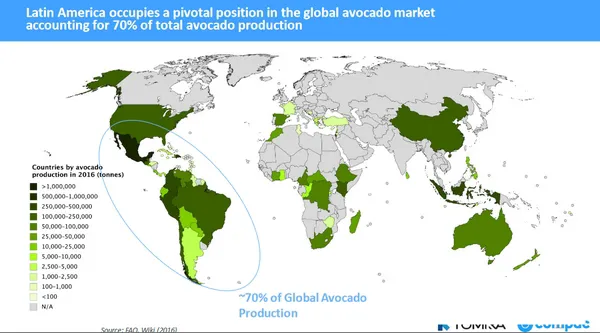

Colombia has a very good opportunity to fill a gap in the avocado supply, when Colombia has avocados no one else in the world is supplying, they do have a 52 week supply but can manage that to have fruit when the market is short.

The technology

Compac's install base is heavily concentrated around New Zealand and Australia, but it also has many customers in South Africa, Latin America, United States, as well as packing facilities in Northern Europe. There are two main forms of facility; the traditional pack and sort model that sits next to where the fruit is grown, and also the re-pack or ripening centres.

Compac focuses on technology for sorting fruit across six categories: avocados, citrus, apples, kiwifruit, stone fruit and cherries. Mr Moynihan says the company turns over US$100million per year, and spends about 8 per cent of its revenue on research and development.

"Our company built the machine that sits in the centre of a packhouse," Mr Moynihan said. "It's the machine that is separating the individual fruit, weighing it and delivering it into a stream of the right size. That has changed dramatically over the last 10 years, and our whole business has really been about the technology, and that's what we sell. That technology is not just weighing the fruit but understanding everything there is to know about the avocado - looking outside and inside every piece of fruit that runs through the supply chain, and then giving that back to the client to make decisions."

"The challenge is how we get the fruit from where it is grown, to where it is consumed," he said. "Also, how we can ripen the fruit when it gets there without losses. The complexity is how we manage multiple different sources; different areas, different farmers, different growing practices in different countries. How do we manage that? To get consistency, you need to consolidate and communicate across different parts of the supply chain, and make sure the operations are running roughly to the same standards."

Technology is constantly improving to help move avocados globally, Mr Moynihan says new devices will soon be available to the supply chain. This includes plastic crates to allow better ventilation when ripening, or 1-Methylcyclopropene (1-MCP) pods that travel with the fruit slowly releasing the treatment, and various coatings that look to extend the shelf-life of the fruit.

TOMRA Insight

The company's Product Marketing Manager, Tim Marshall says another one of the big advantages of the technology is the traceability, especially in terms food safety and efficiency.

"We use a system called TOMRA Insight, which we have been developing over the past two years. The interesting thing is that we had information in our inspection systems, then we had information in our weighing system, and information in all parts of the packhouse.

"We use a system called TOMRA Insight, which we have been developing over the past two years. The interesting thing is that we had information in our inspection systems, then we had information in our weighing system, and information in all parts of the packhouse.

But none of this was connected. So, we created a unique fruit number, and every piece of information across the line, came back to the one piece of fruit. It can help with packout optimisation, how much downtime and how much tonnage. It can also categorise defects such as rub and windburn to come up with a resolution, as opposed to just that it was an 80 per cent packout."

For more information:

Nigel Flack

Compac Sorting Equipmement

Nigel.Flack@tomra.com

Tel: +64 96 34 00 88