Using less plastic is a hot topic at the moment. Where possible, and if the product allows for it, paper or cardboard can replace plastic. Flow packs are a form of packaging where the packaging material weighs relatively little. However, many people think plastic should be banned. A cardboard flow pack is a possible solution.

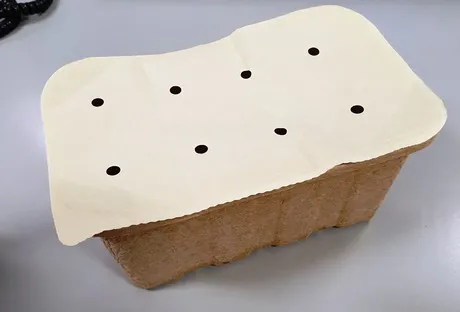

A flow pack made from cartopaper.

A flow pack made from cartopaper.

This kind of paper is called CartoPaper. "It is not anything new," says Ronald Borst of Van der Windt Packaging, a Dutch company. "New applications have just been added. Six months ago, the focus was on packing onions and potatoes in a vertical sealer. Now we can also flow pack these. We have also found top seal possibilities."

"CartoPaper has countless uses. It can even be used with PET. Although, it is not the most obvious combination to seal paper on PET. Yet, this benefits the environment a little. It replaces a small bit of plastic. It is more obvious to seal on pulp or paper. But, since PET sealing is possible, we offer this option."

Packaging machines

This kind of cardboard is water-resistant but does not absorb water. Besides this property, it can easily be processed on existing packaging machines. "Some adjustments must be made to the machine. But, this does not amount to a big investment," says Ronald.

“You have to make the fewest changes to flow pack machines. With vertical sealers, the shoulder will have to be adapted a little. It is too steep for paper. For that matter, it would be best to invest in a machine that can process paper. It is easier to switch these machines to use plastic than the other way round. In the future, I expect plastic and paper to be increasingly used side-by-side."

Not the only solution

With CartoPaper, Van der Windt is following the market trend. "From the public's point of view, there is an aversion to plastic. We, therefore, went looking for other packaging materials. Alternative packaging is not, in my opinion, the sole solution to reducing plastic. There are always two sides to a story. Do you want to recycle the packaging material? Or are you leaning toward compostable material?" Ronald asks.

"PET can, for example, be recycled well. Europe has the recycling process well in hand. For instance, r-PET packaging is very 'in' at the moment. This application is more than ten years old. It is also never made up entirely of 100% recycled plastic. About 80% is recycled. The outer layer is mostly not. Companies are promoting this old idea as something new." This, however, does not distract from the fact that PET can be reused in this way.

When it comes to compostable materials, a lot of money needs to be invested in this type of packaging. It is also not easily recognized as such by consumers. It often does not end up in the compostables bin. And, even if it lands in the correct bin, an expensive material is going to become compost. Re-using it is a much better option.

"There are different ways to look at something's environmental impact. For example, a certain type of packaging's water and energy usage, thickness, weight, and so on. In fact, a life cycle assessment or LCA (thelcacentre.com) is the only way to properly and correctly compare packagings' environmental impact," explains Borst.

Unpackaged goods

Then there is also the possibility of having unpackaged products in the store. "In my opinion, not packaging fruit and vegetables is not the answer. It is public knowledge that a large percentage of fruit and vegetables is already being discarded. Were we were to sell more unpackaged goods, this percentage will only grow. This percentage will increase because the products will have shorter shelf lives. They will be more prone to damage too."

"We would also need some kind of packaging. In supermarkets, conventional and organic fruit and vegetables need to be kept separate. If not, there is a big chance that clients will try to pay less expensive, conventional prices for organic products. Packaging goods in paper is an excellent alternative. After use, this goes into the old paper bin. It gets recycled and gets a second lease on life," Ronald concludes.

For more information: Ronald Borst

Ronald Borst

Van der Windt Verpakking

10 Nieuweweg

2675 BC Honselersdijk

Mob: +31 (0) 651 092 337

Ronald.borst@vanderwindt.com

www.vanderwindt.nl