Individual Quick Freezing, or short IQF, is the method used to industrially freeze a large spectrum of products from fruits, vegetables, to berries, seafood, meat and even cheese and pasta.

This method is used for smaller pieces of produce which need to be separately frozen as opposed to block frozen. But not any IQF freezer can achieve a high-quality product which has a natural appearance, with each piece of product being perfectly separated. So, what are the factors which determine a high-quality IQF freezing? Svetlana Plotean explains:

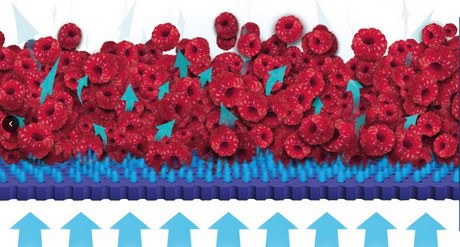

"One element which is of crucial importance when it comes to a truly qualitative freezing is a good fluidization. Fluidization is making the product act like a fluid inside the freezer. It is a phenomenon created by the cold air currents in the freezer produced by the fans. By correctly adjusting the airflow, the product is gently flowing in wave-like motion which both separates each piece of product and also freezes them to the core."

"As OctoFrost company, we have mapped three signs of bad fluidization: First there can be too much fluidization of the product which can damage the product. Too little fluidization can create lumps and blocks of frozen pieces and finally there can be too little movement of the bedplate, which transports the product. This can cause slower and less efficient freezing." Plotean says.

When it comes to key factors of achieving good fluidization, on the other hand, OctoFrost puts emphasis on four elements.

Air pressure underneath the bedplate which creates a pressure drop on the bed lifting and gently moving each piece of product.

Bedplate movement helps to agitate the product, create the wave-like motion and therefore efficiently separate the product.

Bedplate configuration which refers to the size and location of the holes inside the bedplate and which determines the airflow spread and speed.

Product characteristics like the size, water content, shape of the product and the infeed temperature (the product temperature when entering the freezer).

"By correctly juggling and combining these four elements, IQF processors can achieve high-quality frozen products which is a key factor in the success of an IQF business." Plotean concludes.

For more information:

Svetlana Plotean

OctoFrost

Tel: +46 7600 600 81

Email: svetlana.plotea@octofrost.com

www.Octofrost.com