Fresh produce travels the globe to find its way to the end-consumer. The fruit market in particular is very global with about nine percent of all fruits grown being traded internationally. The majority is shipped in refrigerated ocean containers. During the transit process different factors determine the quality of produce upon arrival at its destination. “People look at visual quality as well as safe quality,” says Christian DeBlasio with Purfresh.

Temperature

Temperature is one of these factors. For optimum shelf-life, it’s important to keep the different commodities at appropriate temperatures. Blueberries need to be kept at -1⁰C for instance while the right temperature for pineapples is +6.5⁰C. “Mixing commodities with different temperature requirements negatively impacts shelf-life.”

Air flow

Air flow is another critical factor for fresh produce. Most containers are designed with efficient air flow systems that push cold air through the floor channels. For most fruit and vegetable varieties, steady airflow through the container aids in extended shelf-life for produce. “Many reefer containers have fan economy or quest modes, which means airflow is reduced for energy efficiency reasons. For some cargos that’s good, but certainly not for fresh fruits and vegetables,” said DeBlasio.

Ventilation

Ventilation involves selecting the right mix of fresh air coming in the container. “This also is a really important factor,” shared DeBlasio. Customers can select the mix of fresh air in cubic/meters per hour (CMH). CMH starts at 5 and goes up as high as 200. “In general, wet-salty ocean air is not good for cargo, but closing the vents can be detrimental to certain produce varieties as CO2 levels would build up too high,” DeBlasio mentioned. “In general, the lower the CMH amount, the better. Items such as mangos and avocados can be damaged with high levels CO2 created when vents are fully closed.” Table grapes on the other hand have a low respiration and can handle high levels of CO2. As a result, there is no risk in keeping the vents closed when shipping table grapes.

Controlled atmosphere

Last but not least, controlled atmosphere (CA) can be a key factor. “The longer the transit time, the greater the chance you may need to add CA.” It is much more critical to add controlled atmosphere to a climacteric fruit shipment from South America to Asia (20 to 30-day journey) than to a shipment from Central America to North America with the transit time being about four to seven days. According to DeBlasio, traditional controlled atmosphere will increase CO2 levels and decrease oxygen. This is critical for avocados, blueberries, papayas, and mangos. Many companies offer CA services for containers, but we differentiate ourselves by adding ozone in addition to increasing CO2 and decreasing O2. “Purfresh is one of the only existing options to also address food safety, inside a reefer container, in addition to CA shelf-life extension, when fresh produce is transported overseas.”

Ozone

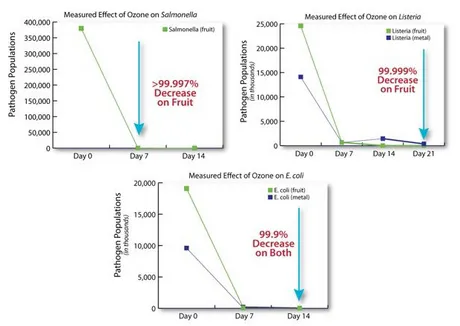

“Quite frequently, we hear about dangerous foodborne contaminations with transported fruit and produce, like E. coli, salmonella and listeria,” DeBlasio shared. “Countries have different regulations on how food is processed and when multiple countries are involved, it becomes difficult to guarantee safety. Ozone reduces the risk of foodborne illness as it sterilizes the container and cargo.” When farms send produce to a shared, central packhouse, produce can become contaminated. “A shipping container can also be a source of contamination as you don’t know what was in the container before your produce.” Ozone will significantly reduce the risk of cross contamination, and it can reduce many types of surface-borne food pathogen risk by as much as 99% in as few as 5-7 days.

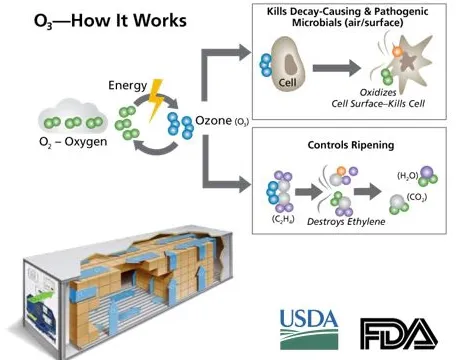

Made from oxygen in the air, ozone kills surface and airborne microorganisms.

Made from oxygen in the air, ozone kills surface and airborne microorganisms.

Many people use ozone for its shelf-life extension benefits as it destroys ethylene, mold, and bacteria. “Few people are aware that in addition to extending produce shelf-life ozone also provides significant food safety benefits,” finished DeBlasio.

For more information:

Christian DeBlasio

Purfresh

Tel: (+1) 813-546-0274

cdeblasio@purfresh.com

www.purfresh.com

www.intellipur.com