Bringing fruit into the market at exactly the right level of maturity poses major challenges for the entire supply chain. But that's exactly what the customer wants: fruit, ready to eat. This same fruit, however, should not ever be overripe. Ensuring the right ripeness at all times is a process that can now be made easier by a new machine that gauges pulp firmness.

Fruit wholesaler Tobi Seeobst has addressed this issue and turned to Bareiss Prüfgerätebau with the accordant measurement problem. The latter company is a specialist in the field of hardness testing of rubber and plastics but is also not an unknown player in the food industry. Bareiss is a pioneer in the field of non-destructive hardness testing of fruit with its so-called pulp fatigue testers.

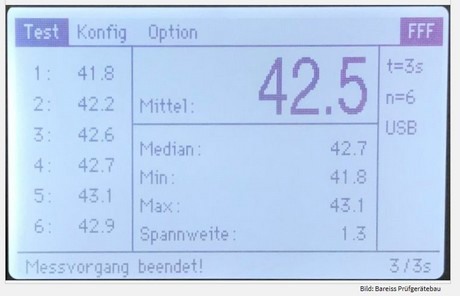

It started with maturity testing of avocados and mangos. Since only hand hardness testers were available on the market so far, Seeobst -in cooperation with Bareiss- has developed a pulp firmness measuring device based on the high-precision measuring device Digi test II. Up to six fruits are placed on the rotating platform and the measurement is hen started with a single click of a button. The device automatically checks all six fruits and generates the measured values as well as several other statistical calculations on the electronic display. The device is easy to use and, according to Bareiss, distinguishes itself by its very high accuracy level.

Fruit ripeness - physical considerations

Physically, the elasticity of the fruit depends on several parameters. Of these, resistance, the measuring path as well as the cross-sectional area and the geometry of the fruit are decisive for the readings of the device. In the fruit, the proportion of insoluble pectins and cell wall stabilizing substances, turgor pressure, fruit shape and size and the position of the measuring point is crucial. The Digi test II FFF from Bareiss and Seeobst's standardized process sequence will reduce the variabilities of the influencing factors mentioned above as much as possible.

Manager Benno Neff of Tobi Seeobst AG

Currently, the device is designed with special probes and recording devices for checking cherries, plums and blueberries, but these can be extended at any time to other fruit types thanks to the modularity with regard to the measuring paths, all with a simple push of the button. This flexibility of the device has already been proven in various field tests: due to the special design of the fruit holders, many types of fruit, from blueberry to apricot, can be measured without the need for time-consuming changes to the measuring equipment. Both pressure plate and the probe can also be easily disassembled and cleaned, should this become necessary do to contamination by some fruit bursting.

For more information:

Tobi Seeobst AG

Bucherstrasse 3

CH-9322 Egnach

Tel. +41 71 474 70 20

Fax +41 71 474 70 29

E-Mail: info@tobi-fruechte.ch

Web: www.tobi-fruechte.ch

Bareiss Prüfgerätebau GmbH

DAkkS -Kalibrierlaboratorium

Breiteweg 1

89610 Oberdischingen

Tel.: +49 (0) 7305 / 96 42-0

Fax: +49 (0) 7305 / 96 42-22

www.bareiss.de