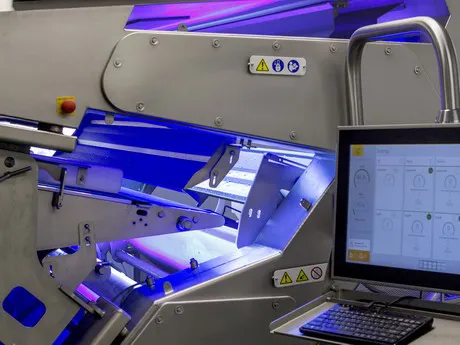

Key Technology, a member of the Duravant family of operating companies, has introduced its new Sort-to-Grade® (STG) software for VERYX ® digital sorters. The patented STG software, which the company says has been field proven for potato strips, is now available for more food sorting applications including fresh and processed fruits and vegetables as well as nuts. Compared to traditional sorting strategies, where a series of one-off accept/reject decisions are made based on fixed selection criteria, a STG-enabled sorter dynamically evaluates each decision based on how it impacts the aggregate ‘in the bag’ grade, as defined by the processor, Key said.

"STG recognizes and categorizes the visual and structural characteristics of every individual object in the product stream. It can allow a specific amount of low- and middle-severity defects to pass, based on user-defined allowable tolerances for each defect category, while ejecting all high-severity defects and foreign material (FM). Accurately passing the maximum proportion of allowed defects for the grade, STG improves process yield. Similarly, when shape/size grading, STG manages the exact ‘in the bag’ distribution required to meet specifications, automatically accounting for variations in the size distribution of incoming product," the company described in a release.

“Our powerful Sort-to-Grade software can evaluate multiple criteria at once. For example, a discoloration may be considered a defect only if it exceeds a certain absolute or relative dimension or if it occurs in combination with other defects on the same object,” said Marco Azzaretti, Advanced Inspection Systems Product Manager at Key. “Processors can eliminate mechanical size grading equipment by using a STG-enabled sorter to control products’ dimensional characteristics. The possibilities of Sort-to-Grade are endless.”

According to the company, VERYX can inspect all surfaces due to its upgraded sensor and can therefore classify each object’s color, size, shape, structural properties and/or chemical composition. "When assessing dimensional characteristics, STG can control minimum or maximum length, width and area or multiple attributes at once in addition to managing the distribution of each dimension within multiple user-defined categories between the two absolutes," it said in the release, adding that the software will result in potentially greater yield as it assesses the batch as a whole rather than by individual fruit.

"Without STG, sorters make accept/reject decisions by comparing the defect, color, size and/or shape of each object to pre-determined criteria, but those decisions are made independently from each other, regardless of the final ‘in the bag’ quality results," the company explained. "Historically, an operator had to adjust the sorter’s accept/reject thresholds subjectively in an effort to make grade given inevitable fluctuations in the quality of the incoming product. This traditional approach to sorting can result in too many acceptable defects being rejected, creating significant yield loss. Or, when incoming defect loads spike, final grade specifications can be missed."

“The value of VERYX with Sort-to-Grade is threefold. It enables processors to address complex product specs to guarantee their quality objectives are met. At the same time, it maximizes yields by passing the ideal amount of acceptable defects, colors, sizes and shapes, all while minimizing operator intervention for better profitability,” said Azzaretti.

For more information:

Anita Funk

Key Technology

Ph: +1 (509) 529 2161

afunk@key.net

www.key.net