A California-based company is continuing to expand its thermaculture heat treatment system into the fresh produce industry. Agrothermal Systems was founded in 2007 and for the past decade has been using heat treatment technology on wine grapes in order to significantly reduce the incidence of pests, diseases and rain damage. The company recently introduced a new machine capable of applying the heat treatment for row and vertical crops, thus allowing for a significantly larger range of produce to be treated.

The Agrotherm XR1 is the first of several new designs made available and works by being pulled by an ATV or Gator type vehicle when in trailer mode or can be lifted in three-point hitch configuration by a conventional farm tractor. The process is fundamentally simplistic and designed to reduce pesticide and fungicide use and even reduce damage caused by rain.

"Thermaculture works by briefly raising the ambient air temperature at and surrounding the plant in a process we call Instantaneous Heat Shock," explained Laura McInerney of Agrothermal Systems. "The results of IHS are numerous - by super heating the air around the plant we are able to disrupt insect and fungal development enough to kill spores and small pests. Heat delivered directly to the plant offers the ability to dry crops after rain events, preventing disease and fungal damage caused by moisture."

"Instantaneous Heat Shock activates the plant self-defense mechanism," she added. "This natural process increases the levels of phenol and antioxidants present in the plant. The effects of which offer improved flavor profiles, additional health benefits, better quality, higher yields, as well as extended shelf-life."

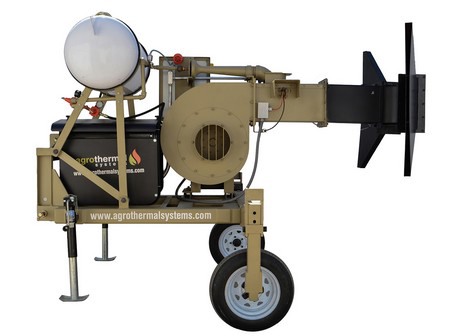

An earlier version of the heat treatment concept

Beginnings

It all started in 2003 when Florencio Lazo Barra, a Chilean grower of grapes, blackberries and cherries designed and patented a machine that was able to be pulled by a tractor and apply heat treatment to agricultural crops. He eventually teamed up with Marty Fischer in 2007 to create Lazo TPC Global, Inc. a California corporation. However, his vision did not go as planned and Lazo began experiencing problems with his original design for the machine. Therefore in 2011, Fischer and a group of investors bought out Lazo's interest in the Company, divided up the patent rights with Lazo, and renamed the company "Agrothermal Systems".

McInerney shared that the company decided to initially focus on wine grapes to improve the chances of success. "The new management team made the decision to focus on one crop large enough to support a profitable business, wine grapes, and to understand and improve upon the basic technology developed by Lazo," she said. "Applications for the broader produce industry were put on hold until 2017, when development of a machine for row crops began. Release of the row crop machine for sales and further development was announced early in 2019."

With the Agrotherm XR1 now in service and available, there are now dozens of different crops that can be heat treated. McInerney listed them including, but not limited to: Baby Greens, Lettuce, Celery, Cabbage, Strawberries, Onions, Green Onions, Tomatoes, Bell Peppers, Cane Berries, Currants, Apples, Peaches, Plums, Nectarines, Olives, Herbs, Table Grapes and Wine Grapes. This includes narrow row vertical crops such as cane berries, herbs, and staked vegetables, the company said.

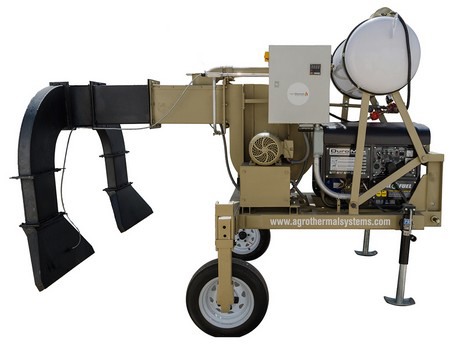

Agrotherm XR1 with vertical vents

Benefits of thermaculture

As mentioned, the idea behind the technology is to use it as a form of pest and disease control, thus reducing the need for pesticides and fungicides. Agrotherm Systems has conducted studies to support its claim that heat treatment can also improve crop yields and lead to improved quality and shelf life.

"Thermaculture is the first of its kind to offer a non-chemical, safe, and effective alternative to traditional and organic chemical spray programs," McInerney said. "At only about $5 per acre per pass, Thermaculture kills insects and fungal spores, improves produce quality, nutrition and shelf life. There is no damage to the plant or crop as the heat shock is brief and quickly dissipates. Ambient temperature returns to normal after about 30 seconds."

She added that this is especially important as more companies look to reduce their environmental footprint, and also in regions where the use of chemicals is more restricted, such as Europe. "In the current environment of increased consumer demand for sustainability, Thermaculture creates no drift, soil or water pollution. It reduces overall water use and requires no hazmat suit, respirator or clean up. Workers are able to spend more time treating crops and less time refilling tanks, cleaning up machinery and protective gear."

Agrotherm XR1 with horizontal vents

Availability

The Agrotherm XR1 was first publicly exhibited at the World Ag Expo in Tulare, CA, in February this year and was also made available to view for interested companies at Fruit Logistica in Berlin. In using heat, the Agrotherm XR1 burns propane to create heat at approximately four gallons/hour costing $6-8 in the US per hour of use. The machine weighs some 1,750 lbs. and sells for $29,900 plus taxes and shipping.

"For produce crops, we are currently available in North and Central America and also Europe," McInerney concluded. "We are working with our development partners to fine tune the technology for row crops. Also, look for new studies being released on powdery mildew in the coming months."

For more information:

Marty Fischer

Agrothermal Systems

Ph: +1 (415) 745-2476

marty@agrothermalsystems.com

www.agrothermalsystems.com