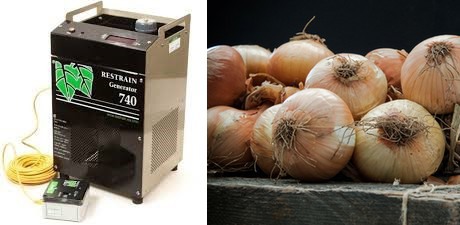

Since 2003, the British company Restrain has been developing ethylene generators and rents them for the whole season to producers of tomatoes, onions and potatoes. This technology from the Netherlands is now sold in 36 countries. The mechanics of the generator are relatively simple: the heat produced by the device converts beet alcohol into ethylene.

Ethylene is a natural plant hormone produced by all plants, especially by climacteric fruits. If the gas synthesized by the machine can be used to speed up the ripening of greenhouse tomatoes at the end of the cycle, it can also delay the germination of tubers like potatoes and onions. If they are placed in a fridge after harvest in September/ October, producers can store them until July of the following year, without germination.

Adrien Fernet, marketing manager France/Belgium at Restrain, lists the many advantages of the device. “The most appealing aspect of the ethylene is that it leaves no residue. So the device is absolutely compatible with organic farming and Zero-Pesticide Residue labels. The gas presents no danger for the staff, the applicator is safe and the onions can be sold right away. The machine is also very easy to use. No special installation in the warehouses or fridges is required, all is needed is an electrical outlet to connect the device. The generators are available for our clients during the entire season. When the contract ends, we come to collect our equipment in order to carry out maintenance work, recalibrate the probes and make sure that the device will be operational for the next season. All the user needs to do is refill with ethanol about once a week. The machine can handle a fridge with a capacity of up to 5,000 tons.”

As for the onion market in France, with the increasing volumes of Zero-Pesticide Residue productions, the demand for ethylene generators is growing. Adrien also adds: “We are the only ones authorized to use ethylene to treat onions. More and more fridges are equipped with our devices. On the global scale, we treat approximately 300,000 tons of onions each year.” The potato sector also presents the company with opportunities for further development. There is indeed another germination inhibitor, namely CIPC, whose authorization at the European level is under discussion. “Our ethylene approach is an alternative to this molecule. We are therefore highly sought after by professionals in the sector who are anticipating a possible ban of the molecule.”

For more information:

Adrien Fernet

Restrain

Phone: +33 786 166 682

adrien.fernet@restrain.eu.com

www.restrain.eu.com