Key Technology, a member of the Duravant family of operating companies, has introduced their enhanced FMAlert™ software for VERYX® digital sorters. FMAlert captures and saves digital images of foreign material (FM) contaminants and can be programmed to immediately alert operators and signal a downstream device during critical FM events. The next-generation FMAlert annotates each image to pinpoint the FM object detected and further eases access to records, the company says. It added that coupled with VERYX’s detection capabilities, FMAlert helps processors control FM, speed response to FM events, recognize trends and improve documentation to protect food safety.

“New food safety regulations and consumers’ rising expectations for product quality are pushing processors to look at more ways to ensure their product is free from FM,” said Marco Azzaretti, Advanced Inspection Systems Product Manager at Key. “Equipping VERYX with FMAlert is a powerful combination. The sorter’s advanced Pixel Fusion™ sensor technology finds smaller and more subtle FM and defects, and it can better identify specific FM types. VERYX removes FM as well as product defects from the product stream with virtually no false rejects; FMAlert adds another layer of protection and helps document the process.”

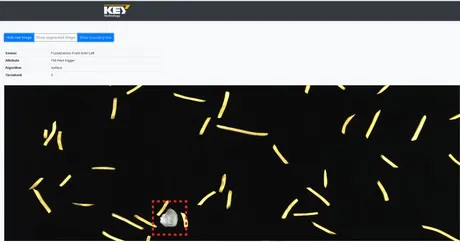

According to Key, the FMAlert captures and saves time-stamped digital images of critical FM present in the product stream and can be programmed to identify specific, user-defined FM types. The software can also be programmed to trigger a smart alarm to alert the operator or team when critical FM is found. ‘Marks’ are digitally placed on the images to point out each critical FM contaminant, so it’s easily seen. The images are saved on the VERYX PC and can be downloaded at the sorter via a USB drive or accessed remotely. It adds that FMAlert’s digital records help identify FM trends, such as recurring FM from a specific product source, and the documentation provides quality assurance to the processor and other stakeholders.

The company also says customers that want to maximize their certainty that all critical FM is removed can use FMAlert to trigger a downstream diverter or dump gate to separate the portion of the product flow where the critical FM was detected.

For more information:

Anita Funk

Key Technology

Ph: +1 (509) 529 2161

afunk@key.net

www.key.net