Builders of banana ripening rooms say that customers are looking for larger capacity rooms and more flexibility when it comes to ripening produce. Interest has grown in the ability to ripen more than just bananas in banana ripening rooms, with ripeners asking companies to design ripening rooms that can accommodate a variety of commodities.

"We have noticed an increase in customers' desire for flexibility in ripening different types of fruits such as avocados, tomatoes and mangoes in banana ripening rooms," observed John Sydoriak of Advanced Cold Storage International (ACSI) who added that this can be achieved in modern ripening rooms. "Multi-product capability is easily achieved with precise temperature control in the ripening chamber."

Energy efficiency

While flexibility and larger capacity rooms are important trends when it come to banana ripening, energy efficiency is another aspect that ripeners are looking for. Sydoriak noted that manufacturers have been improving refrigeration technology in recent years, something that will continue to be a focus moving forward into 2019.

"The desire for energy efficiency is a top concern," he said. "Refrigeration equipment suppliers are staying on top of this with energy efficient cooling systems and pressurization fans producing less heat in the rooms, both of which help to lessen energy consumption. In the next year, I expect to see higher energy savings with further advances in the mechanical equipment of the rooms. The less heat given off by the mechanical equipment, the more efficiently you can cool your product thereby realizing more energy savings."

Remote control

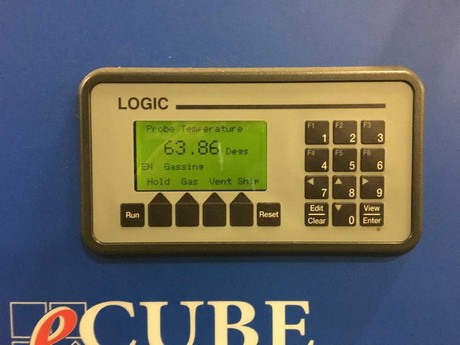

In line with greater automation occurring throughout the produce industry, technology to remotely control atmosphere is progressively advancing. This is also being seen in the world of banana ripening where ACSI provides its customers with software that allows remote access to control their ripening chambers, including adjusting alerts, parameters and temperatures.

"With internet connectivity to the ripening rooms and their software, ripeners can interface with the rooms from anywhere they can connect to the internet," Sydoriak explained. "ACSI has been providing our users access to their rooms via Team Viewer, which gives them direct access to the ripening software allowing remote alarming, remote temperature control, changes to any set points and also allows us to assist in software upgrades and direct tech support if needed."

These trends show that the technology for ripening bananas and other fruit is making strong progress and will continue to move forward this year. In addition to the latest technology, ACSI has also noticed more interest in other regions, including Texas, Mexico and Asia. Sydoriak concluded by saying ACSI is looking forward to another year of success. "We are happy to be in our 13th year in 2019 and would like to thank all of our customers for their continued support!"

For more information:

John Sydoriak

Advanced Cold Storage International

Ph: +1 (715) 398-6357

jsydoriak@gmail.com

www.advancedcoldstorage.com