Irish scientists have used a non-destructive technology (optical sensors) for oxygen (O2) monitoring to evaluate before the level of O2 consumed by individual salad leaves and then to improve the packaging of fresh-cut Italian salad mixes during refrigerated storage.

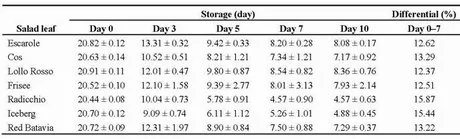

Irish scientists have used a non-destructive technology (optical sensors) for oxygen (O2) monitoring to evaluate before the level of O2 consumed by individual salad leaves and then to improve the packaging of fresh-cut Italian salad mixes during refrigerated storage. The first part of the study consisted of monitoring the O2 utilization in packs by seven individual leafy vegetables commonly found in fresh-cut Italian salad mixes. Each leaf showed varying the respiration rate throughout the storage.

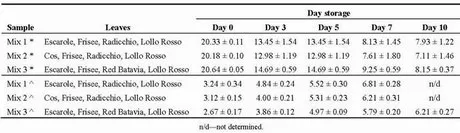

The second part of the study consisted of monitoring the O2 level in packs of Italian salad mixes stored at 4°C for 10 days. According to the results obtained from the O2 level of each leafy vegetable, the scientists prepared a mix (mix 3) with the four slowest respiring salad leaves and compared mix 3 with two commercial Italian salads.

Italian salad mixes tested were:

Mix 1: Escarole, Frisee, Radicchio, Lollo Rosso;

Mix 2: Cos, Frisee, Radicchio, Lollo Rosso;

Mix 3: Escarole, Frisee, Red Batavia, Lollo Rosso

Scientists monitored not only the O2 level in packs, but also analysed the samples in terms of microbial (TPC, total plate count) and sensorial quality (overall appearance, wilting appearance, browning, texture, off aroma, off odours).

Table 1 - Consumption of O2 by seven individual salad leaf types typically used in Italian-style RTE mixed salad leaf products (included standard deviation). Click here to enlarge the table.

Results showed that mix 3 consumed the least amount of oxygen over time, had the lowest microbial load and was the most appreciated in terms of overall appearance.

Table 2 - Represents the mean % O2 by optical sensor (*) and log cfu/g included standard deviation (^) found in each mix on day 0, 3, 5 and 7. Click here to enlarge the table.

This study has demonstrated that optical sensors could be an efficient non-destructive technology to improve and develop fresh-cut products, especially fresh-cut salad mixes, whose respiration rate depends on several factors, such as product typology (single product or mix product), cultivation system, cultivation season, harvest handling, etc.

Source: Hempel A.W., O’Sullivan M.G., Papkovsky D.B., Kerry J.P., ‘Assessment and use of optical oxygen sensors as tools to assist in optimal product component selection for the development of packs of ready-to-eat mixed salads and for the non-destructive monitoring of in-pack oxygen levels using chilled storage’, 2013, Foods, Vol. 2, pagg. 213-224. Further info: http://www.mdpi.com/2304-8158/2/2/213