Banding is becoming an increasingly attractive option for fruit and vegetable packaging. At a time when sustainability and minimizing waste are all important, with legislation and branding being vital too, banding could be the solution, says Bandall. "In recent years, this type of sustainable packaging solution has grown, especially in the fruit and vegetable sector," begins Erik de Roos.

The globally active family business specializes in sustainable bundling and banding solutions for the packaging sector. "Lately, you see people looking for sustainable packaging solutions," adds Hans den Dikken. "Legislation makes plastic packaging solutions increasingly difficult. Full cardboard packaging poses environmental problems."

"And cardboard trays with a sticker are two different materials, making it technically unattractive for recycling. We, therefore, see more and more Dutch and Belgian retailers, like Albert Heijn or Colruyt, switching to mono-materials, which they want to market."

Information carrier

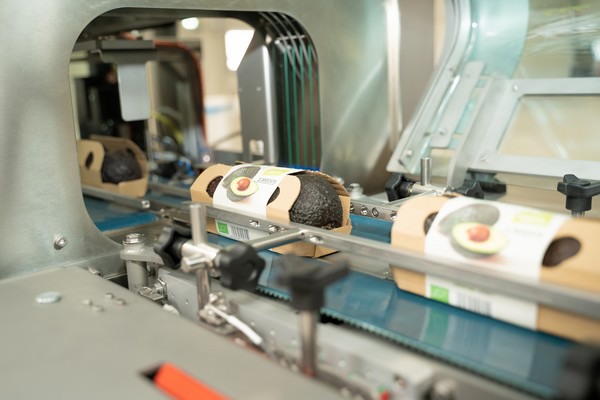

That is where banding technology comes in. "To switch to mono-packaging, retailers choose, for example, a meal salad or container of vegetables or fruit with banding instead of a sticker," says Erik. According to him and Hans, there are two main reasons for this. "On the one hand, there's the issue of recyclable mono-materials; on the other, the packaging must display an increasing amount of information."

"Labels in, say, Belgium must be in three languages, but people also want to communicate more and more using packaging. That's tough with just a sticker. A band, however, offers many possibilities regarding branding or sharing information. Also, even in the shopping bag, the packaging stays tightly closed," Erik explains.

Banding technology offers various options. "You can add banding around trays which can be printed too. A band often serves as an information carrier. But some information can vary, like barcodes, specific product information, or information in a specific language. With an integrated printer, one can simply print that information while banding," says Hans.

Loose bundling

Also, to minimize packaging material, it is becoming increasingly interesting to bundle loose products. "That's not easy because cucumber or pointed bell pepper sizes and shapes differ. The advantage of banding, though, is that during banding, the different contours can accommodate those small deviations," Erik continues.

"The band forms tightly around the product and stays neatly in place. Still, you sometimes run into problems. Cucumbers, for instance, shrink, making them difficult to band. However, there's a new technique in America where they first spray the cucumbers with an edible, odorless plant-based spray, which deters the shrinkage and helps them keep longer. That's great."

Bandall, a Dutch company, operates in about 120 countries and has branches in, among others, the Netherlands, Belgium, the United States, Canada, and Germany. Hans: "Also, in many other countries, such as Spain, Poland, and Italy, we work with solid dealers who may carry our name. That lets us quickly adapt to each global customer's wishes and requirements. That's especially important in the fruit and vegetable sector. Each country has its own legislation and needs, so we want to offer the full range."

Bandall's fruit and vegetable share has risen to around 30%. "Much of our market consisted of food companies, but the fruit and vegetable share has grown tremendously since the plastic issue. Especially in the organic segment, a natural look soon becomes a must. Cardboard trays with fully personalized brown paper banding have long been popular there," Hans explains.

Machine rental

Bandall supplies the entire range, from standalone machines to fully automated banding lines to diverse sectors, and also offers a rental option. "We want clients to have the chance to start banding with a low investment. That could be because they first want to see if they like it," adds Erik.

"But, also, some retailers have temporary promotions, for example. Then after a few months, they decide they want something else and aren't stuck with an expensive machine they can't use. People often tell us they face such hurdles, so we wanted to offer a solution."

Banding, nonetheless, comes with challenges too. "Especially in the fruit and vegetable sector, where high-speed, high-capacity packaging is required. There's, therefore, a need for machines that achieve a decent capacity to compete price-wise with, say, flow pack machines. We offer additional technology to the existing program that can achieve those higher speeds. We expect much from this in the coming years, particularly in the fruit and vegetable sector. We want to continue growing steadily in this way," Hans concludes.

Bandall is at Interpack 2023 in Düsseldorf, Germany. Hall 5, Stand C42.

For more information: Bandall

Bandall

45 Damzigt

3454 PS, De Meern, NL

Tel: +31 (0) 852 735 840

Email: info@bandall.com

www.bandall.com