The dynamics of the Canadian greenhouse industry are getting more sophisticated each year. It's impressive enough to think that hothouse vegetables are growing in a freezing climate, but now these greenhouse growers are taking further steps to bring their produce to a higher level.

The dynamics of the Canadian greenhouse industry are getting more sophisticated each year. It's impressive enough to think that hothouse vegetables are growing in a freezing climate, but now these greenhouse growers are taking further steps to bring their produce to a higher level.

NatureFresh™ Farms, based in Leamington, Ontario, said they are continuing to increase their acreage each year. Production is now ramping up for the season at their Delta, Ohio facility, while in Leamington, NatureFresh are building 32 new acres which are due to be ready by the middle of next year. This will help with the company's push to grow their organic category. This year, around 10 percent of their revenue is made up of organic produce. Next year, it's set to almost double.

"Currently, the level of our organic program is comparable to the rest of the industry at 10 percent, but from next year we are increasing our acreage to have 18 - 20 percent of revenue generated from organic produce, mainly from bell peppers" said Paul Schockman of NatureFresh™ Farms (pictured, top right). "Along with the additional acreage, we will also have our own organic cucumbers. This reflects an industry-wide trend."

Responsible growing practices beyond organics

Greenhouse products offer the consumer an opportunity to have a locally grown product all year regardless of where they live. It removes the natural barrier of climate and enables fresher vegetables that would otherwise come from much further away. NatureFresh™ Farms has taken this a step further by making their greenhouse more energy efficient, to offset significant energy usage and costs. The company also has a system in place to conserve water and use 'good' bugs to help naturally combat unwanted pests.

"We work with the newest and latest technologies with such components as motors and lighting to ensure maximum energy efficiency," Schockman said. "We also continually replace older equipment and infrastructure. With our partner growers, we measure the energy and CO2 impact per kilogram to form an 'energy-cost-per-kilo' measure, which can then be managed. Our irrigation system is in a closed-loop system which helps to conserve water."

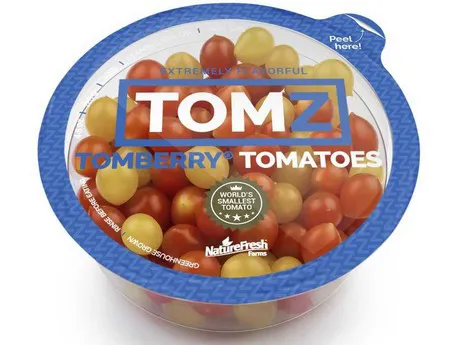

Yellow Tomberry Tomatoes - they are also available in red.

Yellow Tomberry Tomatoes - they are also available in red.

He added that NatureFresh™ Farms also utilizes clean wood waste for their biomass boilers to help heat the greenhouse, which would have otherwise ended up in landfill. "Every year we burn approximately 15,000 tons of clean wood waste in our bio-mass boilers – this product would have been thrown into a landfill and not used productively."

Growing in coconut fiber

The practice of growing produce in processed coconut fiber is becoming more widespread. Essentially, coconut husks are processed and ground into fiber. This is then used as an alternative to Rockwool or soil. According to NatureFresh™ Farms, the coconut fiber holds nutrient water very effectively, while allowing excess water to easily drain. Overall, the company said the fiber provides an ideal and stable environment for the produce to grow in.

"NatureFresh started using coconut husks back in 2003," Schockman explained. "It began when we were disposing of the Rockwool and found that there was nowhere to reuse it. We found coconut husks to be of value to us in that regard as we looked to be a leader in responsible agriculture. Many companies use it now, but some companies haven't made the switch. It can be more difficult to grow in, but with proper care and knowledge, yields can be just as good as if using Rockwool."

The only limiting factor in using coconut husks is that in Canada, produce must be grown in soil to be certified organic and therefore, NatureFresh™ Farms uses it for their conventional produce.

A "very different booth" at PMA

For the PMA Fresh Summit this year, NatureFresh™ Farms is looking to do something a little bit different. The company wants to do more than discuss their programs. They want potential customers to be a part of the evolution of their product range and are inviting them to a "behind-closed-doors" tasting area, one very similar to what they have set up in their facility in Leamington.

"When we look to move products from a trial to becoming commercialized, we have a team of 40 people who are certified food tasters who help decide which products are worthy of further development," Schockman shared. "At PMA, we are going to have our booth set up so that we can show our new varieties to potential customers and let them taste some of our very new products 'behind closed doors', much as we do in our facility."

Additionally, the company will have Virtual reality head sets to "transport" visitors to their greenhouse facility, as well as showcase products like Tomberry® Tomatoes. Schockman emphasized the focus on quality that the company lives by. "A lot of the focus is on quality and taste," he said. "We are prepared to sacrifice a few kilos of product to make sure the quality and taste are optimal and we communicate this to our customers. NatureFresh is more focused on lifestyle and this will be evident at our booth at PMA."

NatureFresh™ Farms will be at Booth #4061.

For more information:

Kara Badder

NatureFresh™ Farms

Tel: +1 (519) 326-1111

info@naturefresh.ca

www.naturefresh.ca