Berry Packing Services (BPS) is located in Venlo, the largest blueberry producing region in the Netherlands. The region, and the company's name, are an indication of what goes on at this business. They are, however, about more than just blueberries. In partnership with various growers, they supply their product to Special Fruit, who co-own the company.

Harm Valckx of Berry Packing Services with the packaging line in the background.

Covered cultivation

"During certain periods of the year, we sort and package blueberries 24 hours a day", says Company Director, Harm Valckx. "We own cultivation areas in the Netherlands and Germany, and since the beginning of the year in Lithuania as well. These are constantly growing in size. Our largest area, consisting of 75 hectare, is in Germany. This year we also acquired 22 hectare in Lithuania, which is the same size we have in the Netherlands."

In addition, Harm is experimenting with a covered cultivation area of four hectare. This will enable his employees to continue working, even when there is bad weather. "We must be able to offer work to people working in the cultivation sector. Even in bad weather", he says. " When the berries are wet, you cannot harvest them. In this case, the workers can continue working in the covered area. When the blueberries are dry again, the workers can go back to the uncovered section. This means they always have something to do. Besides, it is not possible to cover the entire cultivation area. That is far too expensive."

Different countries want different packaging

Although BPS in located in the middle of the blueberry cultivation region, their packaged fruit is not sent to the Netherlands. "We supply the United Kingdom, Scandinavia, and Germany", Harm continues. "Since the Dutch blueberry sector is reasonably saturated, we focus on other countries. Each country has its own packaging requirements. You have been able to find top-seal packaging in the UK and Scandinavia for a while now. In Germany, it is slowly becoming more popular. In Germany, the type of packaging is not as nearly as important as its cost-effectiveness. In the UK, there are environmental taxes attached to the different kinds of packaging. This has somewhat of an affects on their choices. For instance, more tax is paid for a container with a plastic lid than one with a top-seal. In this way, each country, and for that matter each client, has their own packaging requirements."

The open punnets of blueberries, on their way to getting their top-seal.

The machine on the left seals the filled punnets.

Then the packaging gets a sticker. This sticker displays information such as country of origin, shelf life, weight, and the barcode.

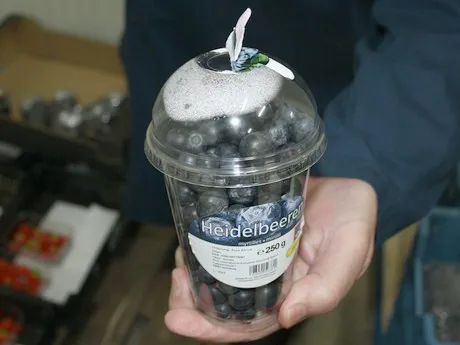

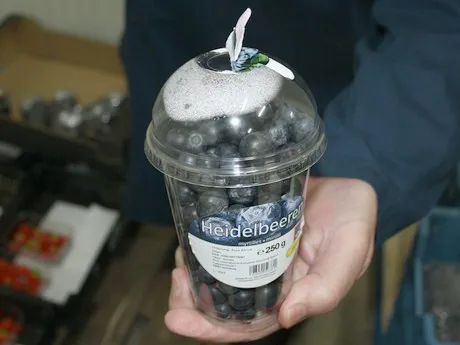

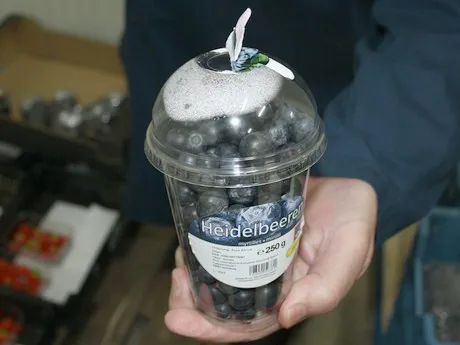

These buckets of blueberries are gaining popularity, according to Harm. He says they do especially well in Scandinavia.

More buckets of fruit

Harm Valckx has noticed that more clients are choosing to have their blueberries packaged in buckets or shakers. "The 500 gram buckets are doing especially well," he says. "We are also selling more shakers with an opening in their lids. This opening is sealed with a removable sticker. This makes consuming the berries, for example in the car, easier and more convenient. It is also going well with the blueberries themselves. Over the last few years, we have seen that the consumption of blueberries has risen by 15 to 20%. This fruit is eaten a lot in especially Scandinavia, but also in Iceland. We supply our berries year round. They can come from a different country each time. The Lithuanian cultivation area can now fill a gap we used to have in our cultivation periods. We certainly want to invest in this region too. The growth potential is very good there. We want to, eventually, increase the 22 hectare to 40 hectare."

The removable sticker is placed at the top of the shaker. This hole makes it easy to eat the berries in, for example, the car.

The removable stickers used to seal the hole in the shakers.

Ideal location

Although BPS is in the Netherlands, but does not supply to this country itself, Harm says that the business is well situated. "Logistically, being in Venlo is fantastic", he admits. "We can be in London or Munich within six hours. The trucks leave in the evenings, and the fruit can be in the shops by morning. It it really quick."

The Berry Packing Services' Director is reasonably satisfied with the Dutch blueberry harvest, even though this year's volumes are not as high as expected. "This is thanks to the frost", he says. "I think we had an 80% harvest, with reasonable prices. The berries were, however, smaller this year since they couldn't grow fully due to the cold spring, but they do taste good. The Netherlands was not as badly affected as Germany, in this regard."

Not only blueberries, but also sugar snaps are packaged in Venlo.

Sugar snaps

Although blueberries are the company's biggest product, BPS sorts and packages more than just this fruit. "Strawberries and sugar snaps are also processed here", Harm continues. "The machine removes the unsightly sugar snaps, and this fresh product then gets packaged. In the case of this product, the machines packages 80 pieces per minute. In January we are getting a second line, so that we can increase the amount of product we package. The process of sorting and packaging the blueberries is about the same. The soft and misshaped berries are removed, and we packaged the good quality ones. We can package 160 punnets per minute. The process for the strawberries is exactly the same, but we packaged about 140 pieces per minute."

The line where the sugar snaps are optically sorted, and later packaged.

The sugar snaps being packaged.

The quality control area for, in this case, strawberries, Bruises and the brix level of the fruit are noted.

The packaged strawberries.

For more information:

Berry Packing Services

Venrayseweg 102C

5928 RH Venlo (Nederland)

T: +31 77 765 00 00